600D Oxford clothThe tearing degree has an impact on the Oxford cloth weaving process, dyeing, and sanding post-treatment processes.

Oxford cloth made of yarns with high strength and elongation will be damaged when torn. The force triangle area is large, and the number of yarns that jointly bear the force is large, the tearing strength is high. The tissue structure and warp and weft yarn density affect the interweaving points and slippage between yarns. If there are fewer interweaving points, the yarns will easily slip, and the tearing strength of the fabric will be high.

The weaving structure is closely related to: plain weave, twill, satin weave, jacquard, etc., and the density of warp and weft yarns; thicker yarns are thinner than thinner ones. The thread shows better strength, twill is better than plain, unsanded is better than brushed, and the less corrosive the dyeing, the better.

Oxford clothThe warp strength and the weft strength are different, and the bursting strength is also different. Whether it includes selvage or not, is it true? Are the edges still raw and whether defects and wrinkles are avoided? In addition, 600 Oxford cloth sizing gray cloth and desizing cloth, dyeing and post-finishing cloth, especially impregnated and special post-finishing cloth, The strength will vary greatly.

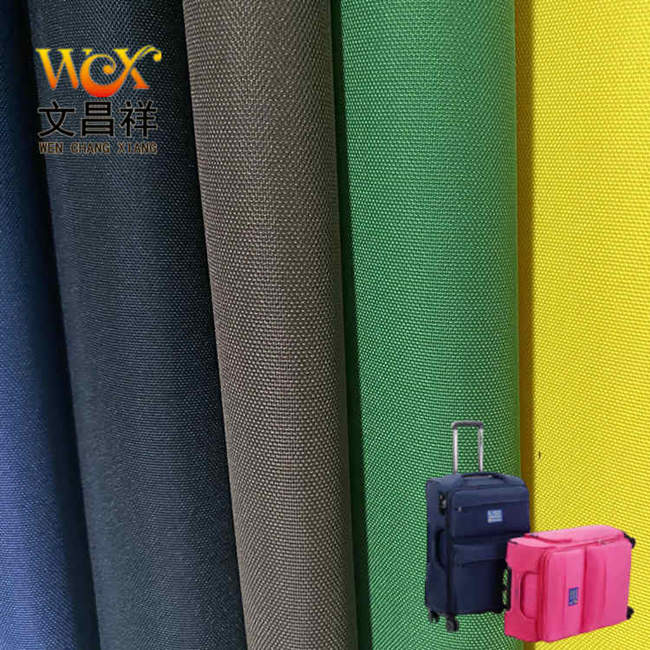

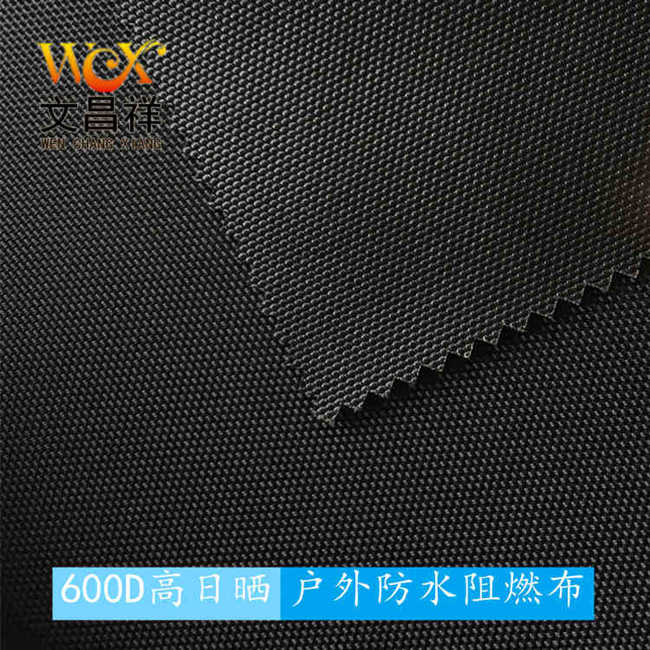

Oxford cloth and environmentally friendly recycled series specifications and classifications: 1680D Oxford cloth, 1200D Oxford cloth, 900D Oxford cloth, 600D Oxford Cloth, 420D Oxford cloth, 300D Oxford cloth, 210D Oxford cloth, 150D Oxford cloth, etc.; classified by function: flame retardant Oxford cloth, waterproof flame retardant cloth, silver-coated flame retardant cloth, pu waterproof Oxford cloth, PVC Oxford cloth, TPE, TPU, Anti-UV, camouflage Oxford cloth, fluorescent Oxford cloth, compound cloth, etc. Please consult customer service for details.

</p