The high oil price correction after March triggered a sharp decline in the polyester chain. When the cost end stabilized, ethylene glycol and PTA took the lead in finding support. At the same time, benefiting from their respective phased warm fundamentals, the market rebounded. However, the high operating rate of the polyester segment is the most important reason to ensure that the two major raw materials do not collapse.

However, due to restrictions in the terminal link, the performance of terminal weaving is not as good as expected, the increase in new orders is limited, overseas orders are lacking, and the inventory of the polyester link is growing rapidly, making the market increasingly worried about the Whether it can support the demand for raw materials.

The short-term market maintains healthy demand for PTA

The second quarter of two 6.6 million-ton Yisheng units Preliminary production

PTA continued to fall after entering March, because the spot processing fee was nearly 500 yuan/ton at that time, which was a relatively high level under the expectation of high production, and there was a downward trend. Motivation to repair. After this round of sharp declines, the processing fee has reached a low level of less than 400 yuan/ton, and the market has also found support around 4,400 yuan. Since the correction last Thursday, affected by the large number of cancellations of warehouse receipts, the spot basis has weakened, dragging down the market performance. The reason behind the continued cancellation of warehouse receipts is the tight supply situation caused by the recent intensive maintenance of PTA.

PTA entered centralized maintenance in April, and its inventory was significantly reduced. Recently, PTA Xinfengming 1#2.5 million ton unit entered maintenance, and Dalian Yisheng’s 2.25 and 3.75 million ton units dropped. Negative 8 load. The PTA load continues to narrow, and the current start-up has dropped to 72.88%. Most downstream polyester factories just need to purchase. The polyester load has slightly declined due to maintenance companies, but the overall fluctuation is relatively limited, maintaining a healthy demand for PTA. However, in the second quarter, PTA is expected to put into operation two units of Yisheng with a total capacity of 6.6 million tons. The future supply and demand pattern is hardly optimistic.

New production capacity of over 3 million tons will be gradually put into operation in April

In the second quarter, the overall pressure on the ethylene glycol supply side was high

In the early stage, ethylene glycol was the strongest among polyesters. The low imports combined with the shrinkage of domestic supply continued to decrease. The pattern of the library made ethylene glycol the first to stabilize and rise. However, as news of the upcoming mass production of satellite petrochemicals came to light and overseas imports began to recover, the reversal in supply expectations caused prices to begin to weaken. Although ethylene glycol stocks are still being depleted significantly in recent weeks, the market expects that the destocking cycle will come to an end. In the past week, the main performance has been significantly worse than that of PTA and staple fibers. Specifically, as the cash flow of various ethylene glycol processes has been restored, the domestic production of ethylene glycol has rebounded significantly since March. The total domestic start-up of ethylene glycol has now risen to around 73%. At the same time, the supply of new production capacity has increased significantly in the second quarter. More than 3 million tons of new production capacity will be gradually put into operation starting in April, and domestic supply is expected to rise significantly. In terms of imports, due to the early maintenance of overseas equipment, domestic import volume decreased, and import volume dropped sharply from February to April. As overseas equipment resumes supply, import volume is expected to gradually pick up from late May. Therefore, the overall pressure on the supply side in the second quarter is on the bias. high.

The influence of demand factors is gradually becoming more prominent

The inventory pressure of polyester companies is increasing

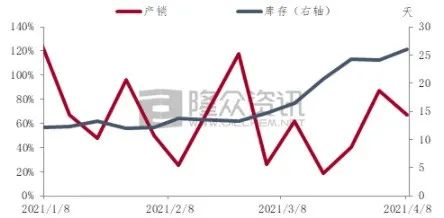

Since March, as raw material prices have dropped and polymerization costs have dropped, polyester filament cash flow has reached its peak in recent years. However, the downward transmission of prices has not been smooth, and the overseas epidemic has not been effectively controlled. The impact of demand is still large, while polyester yarn has increased too fast, gray fabrics are unsaleable, and downstream users are increasingly resistant to high prices. However, polyester filament companies have not lowered prices and are operating stably. Therefore, polyester filament production and sales have continued to be sluggish since mid-March. After the middle of the month, there were some discussions to lower prices, but downstream companies did not buy it. As shown in the figure below, the trading atmosphere in the polyester filament market remained deserted, and inventory pressure slowly increased.

Comparison of polyester filament production, sales and inventory trends in 2021

Inventories continue to accumulate. In early April, polyester filament companies are under great pressure to ship. However, the overall production and sales situation is not satisfactory during the Tomb Sweeping Day holiday. After the holiday, some quotations were raised in a narrow range, further aggravating the market’s selling sentiment. Polyester The inventory of filament yarn companies is under pressure. The higher inventory has reached the level of one and a half to two months, and the lower inventory is more than 20 days old. The influence of demand factors has gradually become prominent.

Due to the impact of sluggish demand, polyester filament companies are focusing on discount promotions near the middle of the month. At this time, downstream users have certain replenishment needs, and the market production and sales volume is high, with a single day high Production and sales are between 1000% and 1200%, and the average daily production and sales reach more than 500%. Because leading companies adjusted their prices earlier, production and sales increased rapidly after the market opened. However, other small and medium-sized enterprises adjusted their quotations later, and most downstream users had already stocked up, so the overall production and sales situation was not as good as expected. Later, some factories continued the preferential model, but the transaction situation was not good.

At present, there are more downstream users than in the early stage of centralized purchasing, and raw material stocks are sufficient. In the short term, except for a few individual companies to make up orders in small quantities, market production and sales are basically at a level of During the downturn, overall production and sales are expected to be around 20% to 50%. The inventory pressure of polyester filament companies has eased, and there is no risk of downward adjustment in the short term. Therefore, in mid-to-late April, the market is basically in a state of consolidation and consolidation. As corporate inventory pressure increases at the end of the month, the market still faces downside risks. A comprehensive look at the market in AprilDemand factors dominate. </p