Classification of commonly used blended dyes

1. Direct blended dyes

2. N-type direct dyes

3. Direct lightfast dyes

1 Dyeing process

Direct Blended dyes

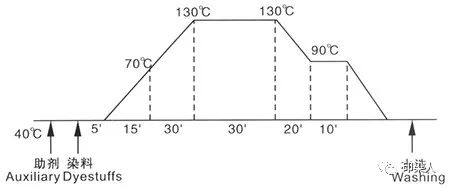

Dyeing process:

1. Polyester/cotton, polyester/viscose blended fabric Dyeing

Disperse/direct blended D-type dye one-bath one-step dyeing process:

2. Dyeing process of cotton fabrics:

Note:

1. Leveling agent: dosage (g/L)

Light color: 1.5-2g/L;

Medium color: 1-1.5g/L;

Dark color: 0.5-1g/L;

(Plain It can also be used as a leveling agent, but the dosage can be reduced by 1/2. However, no matter what kind of leveling agent it is, it is best to add it before adding the dye to ensure uniform dyeing.)

2. Dye accelerator: Yuanming powder (Na2SO4) dosage (g/L)

Light color: 2-5g/ L;

Medium color: 5-10g/L;

Dark color: 10-20g/L;

(It is best to add it in the middle of dyeing to avoid excessive initial dyeing rate and color flowers. Sometimes, salt can also be used, but the amount can be reduced by 1/2-1/3).

3. Color fixation treatment

Floating on the fabric after dyeing The color must be thoroughly washed to avoid being alkaline to fix the color.

Fixing agent 0-4% (o.w.f)

Liquor ratio 1:10-20, 50ºC×20min

The pH value should be 6 (adjusted with HAC) to facilitate polymerization inhibition and improve color fixation effect.

2 N-type direct dyes

Dyeing process:

1. Dyeing of polyester/cotton and polyester/viscose blended fabrics

Disperse/direct blended type D One-bath one-step dyeing process:

2. Dyeing process of cotton fabrics:

Note:

1. Leveling agent: dosage (g/L)

Light color: 1.5-2g/L;

Medium color: 1- 1.5g/L;

Dark color: 0.5-1g/L;

(Pingpingjia can also be used as a leveling agent, But the dosage can be reduced by 1/2. But no matter what kind of leveling agent it is, it is best to add it before adding the dye to ensure uniform dyeing.)

2. Dye accelerator: Yuanming powder (Na2SO4) dosage (g/L)

Light color: 2-5g/L;

Medium color: 5-10g/L;

Dark color: 10-20g/L;

(It is best to add it during dyeing to avoid excessive initial dyeing rate and color flowers. Sometimes, salt can also be used, but the amount can be reduced by 1/2-1/3).

3. Color fixation treatment

Floating on the fabric after dyeing The color must be thoroughly washed to avoid being alkaline to fix the color.

Fixing agent 0-4% (o.w.f)

Liquor ratio 1:10-20, 50ºC×20min

The pH value should be 6 (adjusted with HAC) to facilitate polymerization inhibition and improve color fixation effect.

3 Direct light fast dyes

Dyeing process

1. Dyeing of polyester/cotton and polyester/viscose blended fabrics

One-bath one-step dyeing process of dispersed/direct blended D-type dyes:

2. Dyeing process of cotton fabrics:

Note:

1. Leveling agent: dosage (g/L)

Light color: 1.5-2g/L;

Medium color: 1-1.5g/L;

Dark color: 0.5-1g/L;

(Medium color can also be added As a leveling agent, the dosage can be reduced by 1/2. However, no matter what kind of leveling agent it is, it is best to add it before adding the dye to ensure uniform dyeing.)

2. Dyeing accelerator: Yuanming powder (Na2SO4) dosage (g/L)

Light color: 2-5g/L;

Medium color: 5-10g/L;

Dark color: 10-20g/L;

(It is best to add it in the middle of dyeing to avoid excessive initial dyeing rate and color flowers. Sometimes, salt can also be used, but the amount can be reduced by 1/2-1/3).

3. Color fixation treatment

Floating on the fabric after dyeing The color must be thoroughly washed to avoid being alkaline to fix the color.

Fixing agent 0-4% (o.w.f)

Liquor ratio 1:10-20, 50ºC×20min

The pH value should be 6 (adjusted with HAC) to facilitate polymerization inhibition and improve color fixation effect. </p