At present, all the latest data, from the number of ships at anchorage to the number of ship arrivals, shipping bookings, inventory to sales ratio, paint the same picture: The congestion crisis in the United States has never been more serious. And it’s getting worse.

The freight forwarding version of the congestion surcharge is released

Due to the threat of port congestion On its inland freight network, C.H. Robinson imposed a $175 per container surcharge at several U.S. ports and one inland market starting September 1.

In addition, the port of departure congestion surcharge will be levied on Shenzhen, China starting from September 6.

C.H. Robinson has been established in the United States for 100 years. It has become the number one trucking company in the United States and ranks seventh in global freight transportation. There are more than 218 branches around the world, of which 158 are in the United States.

The company’s move is critical for importers already facing high demurrage and port charges, intermodal rail delays, rail metering of Midwest freight, and truck capacity constraints. For now, surcharges are the latest added cost barrier.

This is another sign that these conditions will continue at least until the end of the year.

Industry insiders pointed out that increased import volume and lack of labor and equipment are part of the reasons for extended stay times and congestion.

The largest third-party logistics provider in the United States recently stated in a customer advisory report: “As you know, the past year has brought unprecedented changes to the transportation industry. challenge. Recently, it has reached a tipping point.”

“As a result, international drayage services serving multiple U.S. ports have implemented a congestion/peak season add-on Fees. What the industry had expected to be short-term challenges is now expected to continue into the first quarter of 2022.”

C.H. Robinson said that from Charleston, Sa. All port terminals in Vanner, Houston, Los Angeles and Long Beach, all rail hubs in New York and New Jersey, Seattle-Tacoma and Atlanta, to local inland point intermodal lines, will be affected by the freight congestion surcharge.

However, the two major ports of Norfolk, Virginia and Oakland, California will not impose this fee. At the same time, it was added that the congestion surcharge imposed this time will last until the end of the year, “We will re-evaluate it at that time.”

In order to justify the surcharge, CH Robinson not only quoted cited port congestion and a loss of transit drivers due to long wait times at port terminals and intermodal rail yards, rail embargoes and a lack of chassis in the southeastern and central United States.

Shortages of even parts needed for truck repairs and a shortage of mechanics are impacting transportation costs and exacerbating congestion, the company said.

It is worth noting that C.H. Robinson not only levies a “congestion proximity fee” at the U.S. destination port, but the company will also levy an origin port congestion fee in Shenzhen, China starting from September 6 Surcharge.

The explanation given by C.H. Robinson is: In recent weeks, the operating costs of handling cargo from the port have “increased significantly”!

With the arrival of the peak season and the increase in cargo volume, importers and logistics companies are currently facing more troubles. The surge in cargo volume has created problems for the ports of Los Angeles and Long Beach, as well as railroads and other regions. Trucking networks bring new pressures.

The truck load index has hit three consecutive record highs and is likely to rise further.

Congestion leads to logistics delays and rising prices

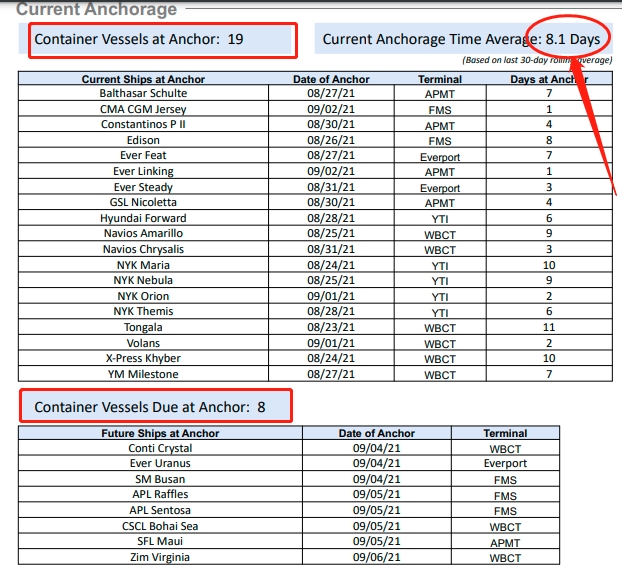

According to the latest data from the Port of Los Angeles signal platform on the 3rd, currently at the Southern California anchorage There are 19 container ships waiting for berths, 8 ships waiting outside the port, and 27 ships waiting. The average waiting time for berthing has increased from 7.6 days a week ago to 8.1 days, and the longest waiting time can be 15 days. .

This “ship jam” phenomenon has led to shortages of goods, logistics delays, and rising prices in many places.

In addition, According to data from the Port of Los Angeles, cargo volume continued to increase significantly in weeks 36 and 37, and the relief is still not optimistic!

Meanwhile, on the East Coast of the United States, trucking was also delayed for about two weeks , which in turn leads to extended container detention time.

Data show that the average detention time of containers in the United States has increased by 35%, which is equivalent to a 35% reduction in available shipping capacity. The long-term detention of containers has further This has exacerbated the growing shortage of chassis in the Midwest and Northeast of the United States. In addition, railway congestion has also led to delays in the delivery of imported goods from the United States, making it difficult for empty containers to be quickly returned to Asia.</p