“Golden nine and silver ten” have always been the industrial characteristics of the chemical market. However, since late October, domestic chemical futures have generally experienced sharp corrections, especially in the coal chemical sector. On the afternoon of the 27th, the domestic futures market closed, and ethylene glycol fell by the limit.

Some market participants told reporters that the main reason is still driven by the weakening resonance of coal prices. The editor learned that relevant departments have recently held a series of coal price limit meetings and clarified the mechanism for ensuring supply and cleaning up illegal production capacity. The market sentiment has clearly reflected the market sentiment, with both thermal coal and double coke falling by the limit, and ethylene glycol, which accounts for more than 36% of the coal chemical plant’s production capacity, also followed the extreme market sentiment and fell by the limit.

The continued rise also triggered downstream conflicts

Polyester filament prices have loosened

The recent strong rise in raw materials has not driven downstream factories to continue to replenish their positions. Starting from the recent period, the spot price of ethylene glycol has plummeted, and polymerization costs have increased sharply. The wait-and-see mood in the downstream is particularly obvious. In particular, traders have begun to flood the market with low-priced goods in the early stage. In addition, factories affected by power restrictions and production restrictions have weak purchasing intentions, making it even more difficult for polyester factories to ship.

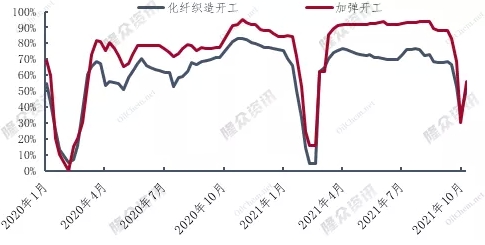

Starting from the middle of the year, the power rationing policy in some areas of Jiangsu and Zhejiang has been gradually relaxed. For example, the Suzhou area has suspended the power rationing policy since the middle of the year, and dyeing and weaving factories are running at full capacity. In addition, since the Zhejiang area, Starting from October 20, the orderly electricity consumption level was adjusted from level C to level B, which caused some factories that were “open three times and stopped four times” to be “open four times and stopped three times”. However, the adjustment of the policy did not stimulate a sharp increase in construction starts in the short term. , especially as the prices of chemical fiber raw materials have been rising, the profits of gray fabrics are relatively limited, and some orders have even been missed, and the production enthusiasm of some factories is difficult to improve. Weaving buyers are less willing to purchase, and the sharp rise and fall have a greater impact on the market, suppressing their purchasing enthusiasm.

Since the fourth quarter of 2021, the price of domestic polyester filament has fluctuated and risen, far exceeding the price of the same period in 2019-2020. The continued rise of polyester filament has also triggered downstream resistance, production and sales The market continues to be sluggish, and the inventory pressure of some varieties is slowly increasing. Some market negotiations have shown signs of loosening at the beginning of the week. The current focus of POY150D/48F negotiations is 8800-9025 yuan/ton, and the focus of high-end and low-end negotiations has slightly shifted down to 25-50 yuan/ton.

Comparison pictures of chemical fiber weaving and texturing in 2021

The current negotiations on polyester filament yarns are showing signs of loosening

Will polyester filament yarns stop rising and enter a downward channel in the fourth quarter?

The current upward trend in polyester filament yarns mainly comes from cost-side support and tight supply issues caused by production restrictions. Specifically, the polymerization cost is currently around 6,600-7,100 yuan/ton. , dual raw materials are currently also gradually consolidating, with little intraday fluctuations, and cost-end support is gradually weakening.

From the demand side, the current dyeing fee prices are constantly increasing. However, weaving companies have great resistance to raising prices. The price of gray fabrics is at a relatively low level. The current profit level is average and production enthusiasm is high. not tall. Even if the power restriction policy is relaxed, the overall weaving operation is still at a low level. Although some manufacturers currently report increased demand for winter orders, the average number of terminal weaving order days at the end of the month was 27.61 days, an increase of 1.11 days month-on-month, but a decrease compared with the same period last year 10.39 days. In the short term, polyester filament may be given certain positive support, but after mid-November, as winter clothing orders are delivered one after another, the market demand for polyester filament will gradually decline. Taking a comprehensive look at the long-short game in the polyester filament market in the fourth quarter, overall the negative news gradually gained the upper hand after November, and there is a certain expectation of a correction in the market.

This week, the “price but no market” situation in the polyester market may still remain, and the Monday sales will also return again!

</p