Since March 2022, the domestic epidemic has been spreading at multiple points and causing local outbreaks, which has had a profound impact on the economic operation of the printing and dyeing industry. Enterprises are facing many difficulties and challenges in normal production and operation. In April, the output of printed and dyed fabrics by printing and dyeing enterprises above designated size reached a periodic low. From January to April, the cumulative output growth of printing and dyeing enterprises above designated size showed negative growth, the export growth rate of main products fell back, the operating efficiency of enterprises declined significantly, and the economic operation of the industry faced periodic difficulties and challenges.

Decrease in production scale

Both ends of production supply and demand are affected

According to data from the National Bureau of Statistics, from January to April 2022, the output of printed and dyed fabrics by enterprises above designated size in the printing and dyeing industry was 17.126 billion meters, a year-on-year decrease of 1.41%, and the growth rate slowed down by 3.34 percentage points from the first quarter, marking the first negative growth since 2021. In April, the output of printed and dyed fabrics by enterprises above designated size in the printing and dyeing industry was 4.723 billion meters, a month-on-month decrease of 10.76%. It was the first time since September 2020 that the monthly output was less than 5 billion meters. In April, frequent epidemics and local outbreaks occurred in many places in China, coupled with the complex and severe international situation, which had a great impact on the production and operation of printing and dyeing enterprises. Printing and dyeing enterprises in the traditional peak season generally faced the dilemma of insufficient orders, and the production capacity utilization of the printing and dyeing industry rate dropped significantly. Analyzing the reasons, from the consumer point of view, the recurrence of the epidemic has had a suppressive effect on the domestic consumer market, and the terminal consumer demand for textiles and clothing is weak. Data from the National Bureau of Statistics shows that from January to April, the sales of clothing, shoes, hats, and knitted textiles in units above designated size across the country Retail sales of goods fell by 6% year-on-year, experiencing negative growth for 2 consecutive months. Online retail sales of physical wearable goods fell by 1.7% year-on-year, the first negative growth since August 2020. At the same time, downstream manufacturers are worried about the impact of the domestic epidemic on product delivery cycles. , adopt the strategy of reducing orders, transferring orders or placing orders cautiously.

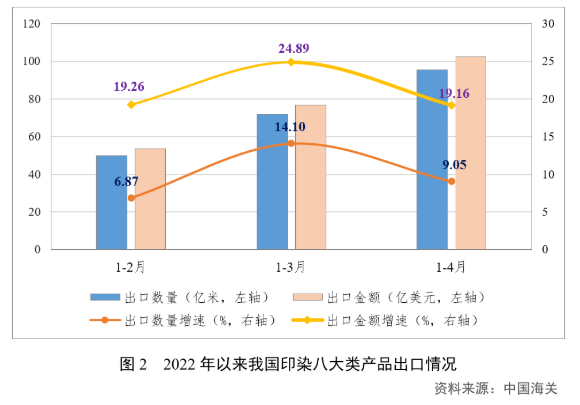

Exports maintain growth

Growth has slowed

According to China Customs statistics, from January to April 2022, the export volume of eight major categories of printing and dyeing products was 9.559 billion meters, a year-on-year increase of 9.05%, and the growth rate fell 5.05 percentage points from the first quarter; the export value was US$10.249 billion, a year-on-year increase of 19.16%, an increase of The speed dropped by 5.73 percentage points from the first quarter; the average export unit price was 1.07 US dollars/meter, a year-on-year increase of 9.27%, and the growth rate dropped slightly by 0.19 percentage points from the first quarter. As many countries around the world relaxed epidemic restrictions, foreign market demand gradually released, and the RMB exchange rate in April was positive for exports. my country’s exports of printing and dyeing products maintained a growth trend. It is worth noting that the export growth rate has slowed down. On the one hand, the epidemic in Shanghai that began in March has affected the logistics and cargo departure of companies in many places. As the world’s largest import and export port, Shanghai Port has led to a decline in logistics efficiency due to epidemic prevention and control, which has directly restricted exports; on the other hand, Foreign supply chains continue to be repaired and production supplies are gradually increasing, which has increased the competitive pressure on my country’s exports. As the domestic epidemic prevention and control situation becomes more stringent, printing and dyeing orders have a tendency to shift to Southeast Asia and other places.

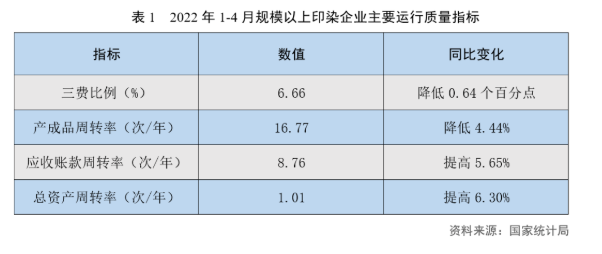

Operation quality deteriorates

Poor connection between production and sales

According to data from the National Bureau of Statistics, from January to April 2022, the proportion of three expenses for printing and dyeing enterprises above designated size was 6.66%, a year-on-year decrease of 0.64 percentage points, of which 6.44% was for cotton printing and dyeing enterprises and 8.22% for chemical fiber printing and dyeing enterprises; the turnover rate of finished products was 16.77 times/year, a year-on-year slowdown of 4.44%; the accounts receivable turnover rate was 8.76 times/year, a year-on-year increase of 5.65%; the total asset turnover rate was 1.01 times/year, a year-on-year increase of 6.30%. The turnover rate of finished products has shown negative growth for two consecutive months, reflecting that due to the impact of domestic epidemic prevention and control policies, the efficiency of enterprise product delivery has decreased, and undelivered products have been backlogged in factories or ports, resulting in the extension of enterprise product delivery cycles. Data from the National Bureau of Statistics show that from January to April, the inventories of printing and dyeing enterprises above designated size increased by 14.65% year-on-year. The poor connection between production and sales has caused companies to slow down the withdrawal of funds, and the growth rate of accounts receivable turnover rate has dropped for two consecutive months.

Economic benefits declined significantly

The cost of production factors is rising

According to data from the National Bureau of Statistics, from January to April 2022, the operating income of printing and dyeing enterprises above designated size was 95.147 billion yuan, a year-on-year increase of 13.82%, a decrease of 3.04 percentage points from the first quarter; the total profit was 3.179 billion yuan, a year-on-year increase of 9.15%, a decrease of 3.04 percentage points from the first quarter. The quarter dropped sharply by 34.13 percentage points; the cost profit margin was 3.52%, down 0.15 percentage points year-on-year; the sales profit margin was 3.34%, down 0.14 percentage points year-on-year; the export delivery value was 13.030 billion yuan, a year-on-year increase of 11.96%. The number of loss-making households among the 1,682 printing and dyeing enterprises above designated size was 605, with a loss area of 35.97%, an increase of 3.78 percentage points year-on-year; the total loss of loss-making enterprises was 1.288 billion yuan, a year-on-year increase of 29.35%, and the growth rate increased by 22.85 percentage points compared with the first quarter..

In April, the economic efficiency indicators of printing and dyeing enterprises above designated size declined across the board, the profitability of enterprises declined significantly, and the losses worsened. The severe domestic epidemic situation has caused some companies to limit production and suspend production. For companies with normal production, their operating rates have dropped due to a shortage of orders, and insufficient production capacity has been released to effectively increase profitability. At the same time, the production costs of enterprises have increased significantly. First, the prices of energy such as natural gas, steam, and electricity have increased significantly. The price of steam in several areas with concentrated printing and dyeing production capacity has increased by more than 20%, and electricity bills have increased by an average of about 15%. Energy is an important production for printing and dyeing enterprises. factors, which have a greater impact on the company’s comprehensive costs; second, the price of raw materials has increased significantly. Since this year, the price of cotton yarn and some basic chemical raw materials has increased by more than 30%; third, logistics costs have increased significantly. As various regions strengthen epidemic prevention and control measures, companies Transportation and logistics are hindered, logistics prices have increased significantly, and even abnormal situations have occurred, which has significantly increased corporate transportation costs. The sharp rise in comprehensive production costs has forced printing and dyeing companies to increase processing fees. However, considering the tolerance of downstream customers and the overall weak market consumption, the increase in processing fees has not been as high as the cost increase, and corporate profit margins have been squeezed.

Overall, affected by factors such as the impact of the domestic epidemic and the more complex and severe international situation, the development quality and efficiency of the printing and dyeing industry declined in April, and corporate profits were obviously under pressure. As the national epidemic situation gradually stabilizes, enterprise production will be on track in an orderly manner. The continued efforts of national-level tax reduction and fee reduction and bailout assistance policies will effectively reduce the burden on market entities and ease the operating pressure of enterprises. Policies and measures to promote consumption in various places will help expand effective demand, promote consumption replenishment and release potential. The production situation and operating efficiency of the printing and dyeing industry are expected to gradually improve.

</p