Record of independent sewing of welding gun jacket

The road is solid and far away, but you can reach it if you work hard; no matter how big the task is, you will achieve it if you persevere. The continuous development and progress of Auto Body Andrade Shanghai Factory cannot be separated from the efforts of everyone. We have many doers who water the harvest with sweat and move forward with determination with hard work.

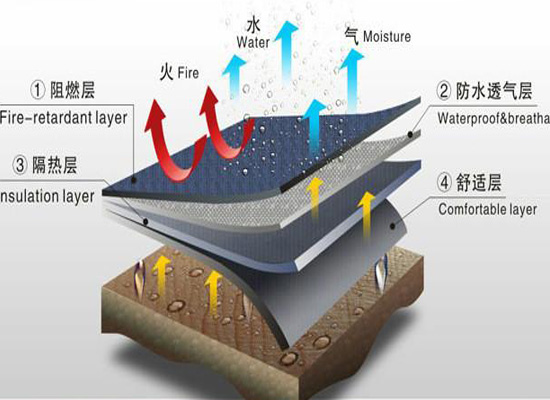

As a key protective device to protect the gun body and pipelines from high-temperature welding slag, the welding gun jacket is very important in the welding production process. However, the cost of gun jackets is very high, about more than one thousand yuan per set. The cost of replacing a set of gun jackets makes the already insufficient maintenance funds even worse.

Special flame retardant for rubber, halogen-free environmentally friendly flame retardant TY-330, various flame retardant series products

There are many types of flame retardants, which can be divided into: organic flame retardants and inorganic flame retardants. The representative flame retardants are chlorine-based, bromine-based, phosphorus-based, aluminum hydroxide, magnesium hydroxide, etc. There are three major categories of organic flame retardants with different characteristics:

The first is brominated flame retardants: most of them decompose at 200°C to 300°C. During decomposition, they capture the free radicals generated by the degradation reaction of polymer materials, delaying or terminating the combustion chain reaction, and the HBr released is a refractory gas. , can be covered on the surface of the material to block flammable gases on the surface. Brominated flame retardants have a wide range of applications and are currently one of the most produced organic flame retardants in the world. The main products include decabromodiphenyl ether, decabromodiphenyl ethane, etc.

The second is phosphorus flame retardant: it is also a flame retardant with good flame retardant properties. Driven by the global trend of non-halogenated flame retardants, a lot of research has been conducted abroad on this. The flame retardant effect of red phosphorus is better than that of phosphate esters. Its usage is also increasing. Phosphorus-containing inorganic flame retardants have good thermal stability and are non-volatile. It has been widely used due to its advantages of not producing corrosive gases, long-lasting effect, and low toxicity. TY330 is made of “surface-treated red phosphorus” as the main material and compounded with other halogen-free flame retardants. Compared with the original red phosphorus flame retardant made of “ordinary red phosphorus” as the main material, it has a finer particle size , better dispersion, less addition amount and other advantages, especially the compatibility with colloids has been greatly improved and improved.

Inorganic flame retardants have a high decomposition temperature. In addition to their flame retardant effect, they also inhibit the generation of smoke and hydrogen chloride. At present, the consumption of inorganic flame retardants in foreign industrialized countries is much higher than that of organic flame retardants. The main varieties used are aluminum hydroxide, magnesium hydroxide, red phosphorus, trioxide, etc. Aluminum hydroxide is a flame retardant that combines three functions: flame retardant, smoke suppression, and filling. It is non-toxic, non-corrosive, has good stability, does not produce toxic gases at high temperatures, is low in price, and comes from a wide range of sources. Magnesium hydroxide decomposes between 340°C and 490°C. It has good thermal stability, good flame retardant and smoke elimination effects, and is especially suitable for processing polyolefin plastics with higher temperatures. Aluminum hydroxide and magnesium hydroxide can complement each other when used in combination, and their flame retardant properties are better than when used alone.

The advantages of halogen flame retardants are low dosage, high flame retardant efficiency and wide adaptability. However, its serious disadvantage is that it generates a large amount of smoke and toxic and corrosive gases during combustion, which is very harmful. In recent years, the development of halogen-free flame retardants to replace halogen flame retardants has become a global flame retardant development trend. Research and development of new flame retardants to reduce the amount of smoke and toxic gases when materials are burned has become a trend in recent years.One of the key research topics in the field of flame retardancy. It has good flame retardant effect and low cost. It can be both flame retardant and smoke suppressor. It also has some special functions. Commonly used synergistic systems are mainly halogen-phosphorus, antimony-phosphorus, phosphorus-nitrogen, etc., to achieve the purpose of improving flame retardant performance. Red phosphorus is one of the main flame retardant synergists. It has synergistic effects on aluminum hydroxide, nitrogen and other flame retardant systems.