Introduction to flame retardant fabrics

01

The concept of flame retardant fabrics

Flame retardant fabrics are special fabrics that can delay the burning of flames. It does not mean that they will not burn when in contact with fire, but that they can extinguish themselves after isolating the fire source. Generally divided into two categories, one is the fabric that has been processed to make it flame retardant, such as polyester, pure cotton, polyester cotton, etc.; the other is the fabric itself that is flame retardant, such as aramid, nitrile cotton, DuPont Kevlar, Nomex, Australian PR97, etc. According to whether it has flame retardant function after washing, it can be divided into washable, semi-washable, disposable and permanent flame retardant fabrics.

Polyester flame retardant fabric is finished with new ATP flame retardant. It has the characteristics of water resistance, excellent flame retardant effect, good hand feeling, non-toxic and safe. This product does not contain halogen and complies with ecological and environmental protection requirements. Its main technical indicators are at the international level. The flame retardant index of polyester flame retardant fabrics can reach national standard B2 or above. It can be washed more than 30 times.

Pure cotton flame-retardant fabric, finished with new CP flame retardant, has the characteristics of water absorption resistance, good flame retardant effect, good hand feel, non-toxic and safe. This product complies with ecological and environmental protection requirements, and its main technical indicators are at the domestic level. The flame retardant index of polyester flame retardant fabrics can reach national standard B2 or above. It can be washed more than 20 times.

Nomex permanent flame retardant fabric is made of innate flame retardant fibers through spinning, weaving and dyeing. The fabric has the characteristics of flame retardant, wear-resistant, temperature-resistant, washable, acid and alkali resistant, waterproof, anti-static, high strength, etc. It is an ideal fabric for making protective clothing in metallurgy, oil fields, coal mines, chemical industry, electric power, and fire-fighting industries. .

Typical flame retardant fabrics are as shown in the table above

02

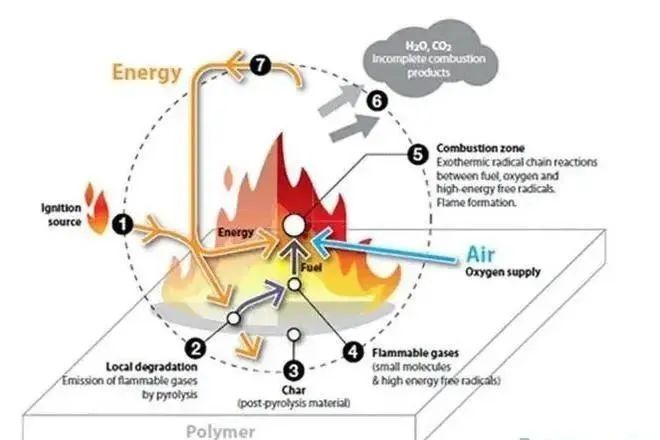

The mechanism of flame retardant fabrics

In actual production applications, the organizational structure and fiber content of textile fabrics are different, and the corresponding types of flame retardants are also different. Therefore, the actual flame retardant effect and flame retardant mechanism are not determined in a single way. The flame retardant mechanism of flame retardants may involve the combined effect of the following flame retardant mechanisms.

1. Covering layer flame retardant mechanism

Flame retardant covering is a chemical change that occurs when the flame retardant is heated and burns, producing flame-retardant substances on the surface of the textile fabric, forming an insulating covering layer.

This covering film can block the interaction between the fabric and oxygen and heat sources, and can hinder the diffusion of flammable gases, thus playing a flame retardant role. Both inorganic and organic flame retardants have a covering flame retardant mechanism. For example, ammonium polyphosphate flame retardants use a covering flame retardant mechanism.

2. Vapor phase flame retardant mechanism

3. NFPA-701 and 703 are fire protection standards published by the National Fire Protection Association, which are applicable to hanging fabrics such as curtains in public places that do not require water resistance. The test also requires physical and chemical indicators such as dry adsorption capacity and hand feel.

4. The full name of TB-603 is BHFTI CTB-603, which was implemented in the United States on January 1, 2005. Mainly used for mattresses, mattresses and other bedding products. The test method is: use the large chamber combustion method to test the heat release value of a complete mattress (mattress).

5. NFPA261.94 is suitable for furniture covering strong objects, including sofas, etc.

6. FAR25-83 Fire protection standards required for aircraft interior decorative fabrics.

(2) Japanese standards for flame retardant fabrics:

1. JISL1008-69 Fire Protection Standard for Aircraft Decorative Fabrics;

2. JISL1091 protective clothing standard;

3. JIS1201=FMVSS302 Fire Protection Standard for Automotive Decorative Fabrics;

(3) British standards for flame retardant fabrics:

1. BS7177 (BS5807) is suitable for furniture and mattresses and other fabrics in public places in the UK. Special requirements for fire resistance and strict testing methods are required. Fire is divided into eight fire sources from 0 to 7, corresponding to the four fire protection levels of low, moderate, high and extremely high danger.

2. BS7175 is suitable for permanent fire protection standards in hotels, entertainment venues and other crowded places. The test requires passing two or more test fires of Schedule 4 Part 1 and Schedule 5 Part 1.

3. BS7176 is applicable to furniture covering fabrics, which are required to be fireproof and washable. During the test, the fabric and filling are required to meet Schedule 4 Part 1, Schedule 5 Part 1 and smoke density, toxicity and other test indicators. It is a fire protection standard for padded seats that is more stringent than BS7175 (BS5852).

4. BS5452 is applicable to bed sheets and pillow textiles in public places in the UK and all imported furniture. It is required that they can still be effectively fireproof after 50 times of washing or dry cleaning.

5. BS5438 series: British BS5722 children’s pajamas; British BS5815.3 bedding; British BS6249.1B curtains.

(4) German standards for flame retardant fabrics:

1. DIN-4102 (DIN66084) fire protection standard for decorative fabrics;

2. DIN23320 and DIN54336-80 (DIN66083) fire protection standards for protective clothing;

(5) French standards for flame retardant fabrics:

1. NFG07-184 protective clothing fabric;

2. NFG92-501-505 fire protection standard for decorative fabrics;

(6) Domestic standards for flame-retardant fabrics:

The national standard divides flame-retardant fabrics into three levels: B1 (flammable materials), B2 (combustible materials), and B3 (flammable materials). They are unified according to GB/T 5455-2014 “Textile Burning Performance Vertical Damage Length, Smoldering and duration determination” and GB/T 5454-1997 “Textiles Combustion Performance Test Oxygen Index Method” for testing.

Normally, flame-retardant products that have been processed by the ordinary impregnation method have a higher pass rate in the vertical combustion test, and the failure rate often occurs mainly in the oxygen index (Ol) test item. It is difficult for general textile products to reach the conventional B2 level without flame retardant treatment. For textile products treated by ordinary impregnation methods, the oxygen index can reach more than 26%. For B1 grade textile products that require the oxygen index to reach the flame retardant range of 32%, manufacturers need to use more complex methods such as padding and baking, dipping and drying or flame retardant the fibers in the product flame retardant treatment process. deal with.

It is difficult to achieve the conventional B2 level through flame retardant treatment. For textile products treated by ordinary impregnation methods, the oxygen index can reach more than 26%. For B1 grade textile products that require the oxygen index to reach the flame retardant range of 32%, manufacturers need to use more complex methods such as padding and baking, dipping and drying or flame retardant the fibers in the product flame retardant treatment process. deal with.