Textile fabric flame retardant technology prevents you from “burning”

Summer and autumn are the seasons when fires occur frequently in my country, and fires cause countless injuries and losses. It must be admitted that the occurrence of fires is somewhat accidental and even difficult to prevent, but even so, continuous improvement of prevention work is still the most important part of responding to fires and minimizing fire hazards. Safety is no small matter.

In order to prevent the occurrence of fire, in addition to taking fire prevention measures, textiles with flame retardant properties, such as flame retardant fabrics and flame retardant work clothes, can also be used to delay the expansion of the fire and give people time to evacuate or take measures to extinguish the fire. Therefore, the research, development and innovation of flame retardant technology is particularly important.

Permanent flame retardant fabrics are highly recommended

What are flame retardant materials? General materials, such as polyethylene plastics, etc., are flame-retardant after adding some flame retardants and then re-mixing. Then flame-retardant chemicals are placed in the materials and re-processed to become flame-retardant materials. The characteristics of the materials are The ignition temperature point increases and the rate of combustion slows down. Flame retardant material is a protective material that can prevent combustion without burning easily.

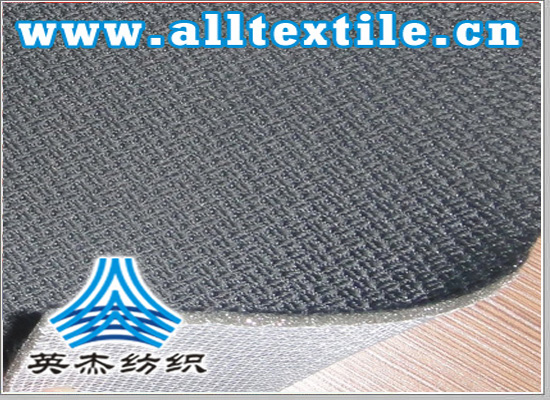

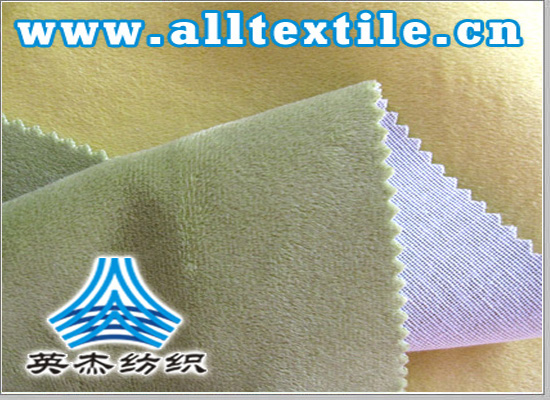

After flame-retardant treatment, textiles can reduce their flammability to varying degrees, significantly delay their combustion efficiency during the combustion process, and can quickly self-extinguish after leaving the fire source, making them less likely to burn. Fabric flame retardant finishing is to fix the flame retardant on the fiber and fabric through chemical bonding, chemical adhesion, adsorption deposition and non-polar van der Waals force combination, so that the fabric obtains flame retardant properties.

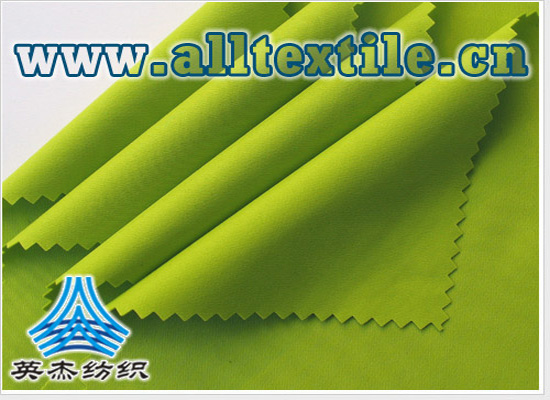

Flame-retardant fabrics can be divided into two types in terms of technology: permanent flame-retardant fabrics and finishing flame-retardant fabrics. Among them, permanent flame-retardant fabrics add certain flame retardants to the raw fibers in the fabric, such as polyester, aramid, acrylic, etc., to change the thermal decomposition process of the fibers and promote dehydration and carbonization. Some make the flame retardants decompose. The non-combustible gas is released to cover the surface of the fiber and isolate the air. The permanent flame retardant treatment mainly makes the fabric have a permanent flame retardant effect by improving the thermal stability of the fiber-forming polymer and flame retardant modification of the original yarn. Post-finished flame-retardant fabrics mainly perform surface treatment on the fabric during the post-finishing process of textiles, so that the fabric has flame-retardant properties.

Compared with permanent flame retardant fabrics, the initial flame retardant performance of post-finished flame retardant fabrics is not much different. However, since the flame retardant of post-finished flame retardant fabrics is attached to the surface of the fabric and has not penetrated into the yarn, After being washed or the use time increases, its flame retardant effect will gradually disappear, so the development prospects of permanent flame retardant fabrics are increasingly being discussed.