Comprehensive analysis of TPU car clothing base film

TPU (Thermoplastic polyurethanes), named thermoplastic polyurethane elastomer, is a type of polymer material between rubber and plastic. It was first successfully developed by the German company Bayer in 1958. The American Goodrich Chemical Company (now renamed Lubrizol) first registered the TPU brand name Estane in 1958.

TPU has excellent physical and mechanical properties. It can be plasticized by heating and solidified by cooling. TPU has both the high elasticity of rubber materials and the high strength of engineering plastics. It has excellent comprehensive properties such as high strength, high toughness, high elasticity, high modulus, as well as resistance to chemical corrosion, wear resistance, oil resistance, and strong shock absorption ability. , is widely used in shoe materials, cables, films, pipes, automobiles, medical and other industries.

From the perspective of TPU market demand, shoe materials currently account for the largest proportion, accounting for nearly 30% of the entire TPU market demand. Next is the machinery industry, accounting for about 28%, while the pipes, automobiles, and construction fields each account for about 10%.

△TPU demand areas

– Application of TPU base film in the automotive field –

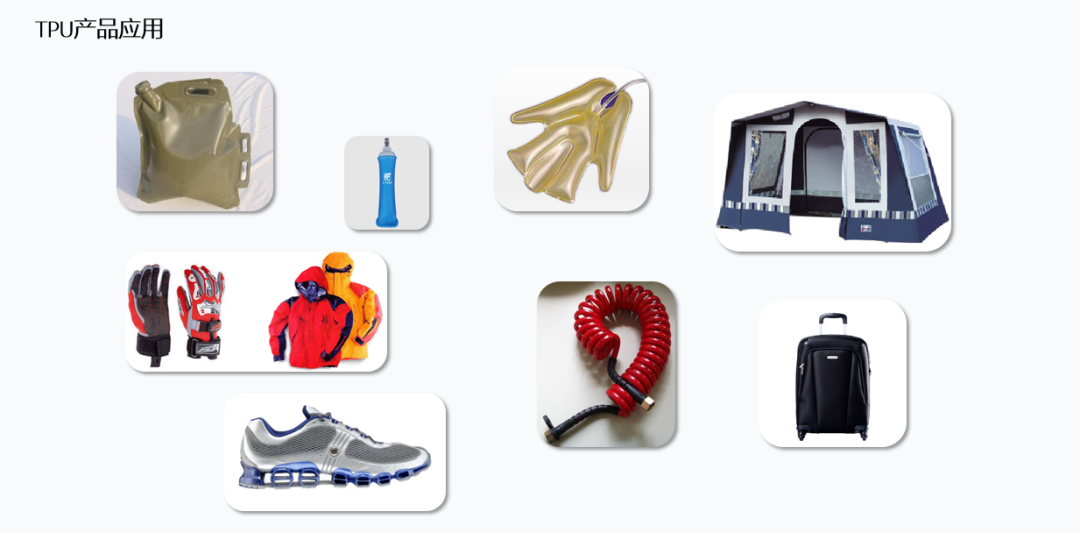

TPU film is an important application form of TPU materials. TPU film is a film made from TPU granules through special processes such as calendering, casting, film blowing, and coating. Because TPU film has the characteristics of high moisture permeability, air permeability, cold resistance, heat resistance, wear resistance, high tension, high pulling force, and high load support, its application is very wide, and TPU film can be found in all aspects of daily life. For example, TPU films are used in packaging materials, plastic tents, water bladders, luggage composite fabrics, etc.

At present, TPU films are used in the automotive field, and the TPU invisible car clothing that attracts the most attention is none other than TPU.

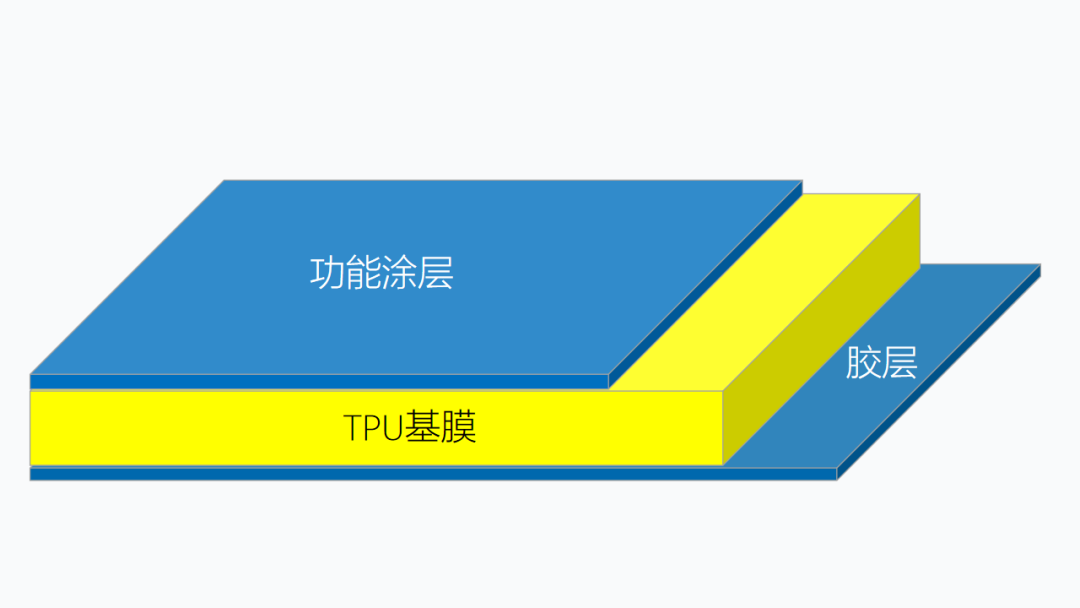

Structurally speaking, TPU invisible car clothing is mainly composed of functional coating, TPU base film and adhesive layer. Among them, the TPU base film is the soul of invisible car clothing, and its quality is very important, and its performance requirements are extremely high.

△TPU car clothing film composition

– In-depth analysis of common problems with car film –

Yellowing and hydrolysis are currently the two most common problems in the PPF market, harming the interests of end consumers. This shows that there are still some problems in the application process of TPU base film. From the production level, whether it is the selection of the base film or the cooperation between the base film and coating, there is some confusion and room for improvement.

yellowing problem

After using the normal TPU base film for a period of timeIt is superior to other materials in terms of strength, haze resistance and yellowing resistance.

Compared with other TPU products, Lubrizol’s ESTANE® TPU has more than 30 years of application experience in the PPF field, has won a wide reputation for its consistent reliability, and has become the industry’s preferred TPU material.

– Production technology and innovative applications of TPU base film –

High-quality TPU granules in the upstream are the foundation, and the production of TPU base film in the downstream is also an extremely important part of the PPF industry chain.

Affected by technical level and other factors, high-quality TPU base films are difficult to find in the domestic market. As a pioneer of domestic TPU base films, Kaiyang New Materials has produced TPU base films that have been recognized and supported by customers in terms of quality and reputation.

TPU base film is usually produced by the casting method. The so-called casting method is a process that melts the particles through an extruder and then uses a mold to cast them into sheets or films. Since TPU is difficult to plasticize uniformly and the film is elastic, the requirements for process control accuracy are very high. Especially aliphatic TPU has high viscosity, so problems such as old glue and slag accumulation are prone to occur during the casting process, which will have a huge negative impact on film quality. Kaiyang has designed a new film production line through independent research and development and technological innovation. In the production of TPU base film, the above problems have been perfectly solved