Classification and selection of non-metallic and composite air ducts!

☞Classification and application scope of non-metallic and composite air ducts

Commonly used air ducts in ventilation and air conditioning projects include metal air ducts and non-metal composite air ducts. Non-metal composite air ducts are divided into non-metal air ducts and composite air ducts according to their structural forms.

Non-metallic air ducts: Air ducts made of non-metallic materials such as fiberglass plates, rigid polyvinyl chloride plates, and fireproof boards. Common ones include inorganic fiberglass ducts, rigid polyvinyl chloride ducts, fireproof board ducts, etc. Inorganic FRP air ducts are divided into two types according to the properties of their gelling materials: one is hydraulic inorganic FRP air ducts made of sulfates as gelling materials and glass fiber mesh, and the other is made of modified chlorine An air duct made of magnesia cement as the cementing material and medium-alkali or alkali-free glass fiber cloth as the reinforcing material.

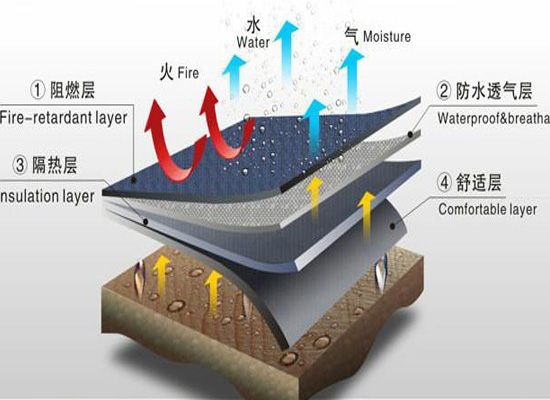

Composite air duct: an air duct made of non-combustible materials as the covering layer and reinforced with composite insulation material panels sealed with tape or glue. Common ones include fiberglass composite ducts, phenolic aluminum foil composite ducts, polyurethane aluminum foil composite ducts, color steel plate insulation composite ducts, glass magnesium composite ducts, aluminum foil and flame retardant cloth hoses, etc. The thickness of the surface aluminum foil should not be less than 0.06mm. When the aluminum foil layer is compounded with reinforcing materials, its thickness should not be less than 0.012mm.

Non-metal composite air ducts are divided into ordinary air ducts and fire-resistant air ducts according to their fire resistance.

The combustion performance of non-metallic and composite air duct materials should comply with the requirements of non-combustible grade A or flame-retardant grade B1 stipulated in the current national standard “Method for Classification of Combustion Performance of Building Materials” GB8624. The fire resistance limit of fire-resistant air ducts should be at least 1h.

The technical parameters and application scope of non-metallic and composite air duct plates are shown in the table below:

☞Selection and installation of non-metallic air ducts

1) The air ducts of ventilation and air conditioning systems in large-space buildings such as gymnasiums, exhibition halls, terminal (car, ship) buildings (halls), single- and multi-story office buildings, and Category C, D, and E factories should not cross fire-proof buildings. When partitioning and installing fire dampers across room partitions, flame-retardant materials can be used.

2) Air ducts in contact with corrosive media can be made of flame-retardant materials.

3) The air ducts and their insulation materials within 2.0m on both sides of the fire damper should be made of non-combustible materials.

4) When an electric heater is installed in the air duct, the air ducts within 0.8m before and after the electric heater and the air ducts that pass through rooms with high temperatures, fire sources, etc. that are prone to fire should be made of non-combustible materials.

5) When the air duct passes through the floor slab or side wall that needs to be sealed, except for the inorganic fiberglass air duct, a metal short pipe or an outer metal casing should be used. When the air duct passes through a fire-proof or explosion-proof floor or wall that needs to be sealed, a steel embedded pipe or protective casing with a wall thickness of not less than 1.6mm should be installed. The air duct and the protective casing should be made of non-combustible and human-resistant materials. Harmless flexible material sealing.

6) The connection of composite air ducts should be socket-step bonding, plug-in connection or flange connection.

7) When connecting non-metallic air ducts and composite air ducts to metal air ducts and equipment, “h”-shaped metal short pipes should be used as connectors. One end of the short pipe is a flange, which is connected to the metal air duct flange or equipment flange; the other end is an “h” shaped socket with a depth of not less than 100mm. Non-metallic air ducts or composite air ducts should be inserted into the “h” shaped socket. mouth��, and use rivets to fix it firmly and seal tightly.

7) Non-metallic air ducts are dimensioned with the inner side length (or inner diameter).

☞Selection of air duct connection sealing materials

The sealing material for air duct connections should be selected based on the temperature of the conveyed medium and should meet the functional requirements of the air duct system. The combustion performance and heat resistance of air duct flange gasket are shown in the table below.

Key points for selecting flange gasket:

1) The thickness of flange gasket should be 3~5mm.

2) To transport air with a temperature lower than 70°C, rubber sheets, closed-cell sponge rubber sheets, sealing tapes or other closed-cell elastic materials can be used; when transporting air with a temperature higher than 70°C, high-temperature resistant materials should be used.

3) The smoke prevention and exhaust system should be made of non-combustible materials.

4) To transport gases containing corrosive media, acid-resistant rubber or soft polyethylene plates should be used.

5) The clean air-conditioning system should use materials that do not produce dust, are not easy to age, and have a certain degree of strength and elasticity. The thickness should be 5~8mm. Latex sponges, thick cardboard, asbestos rubber sheets, lead oil, linen silk, and linoleum paper should not be used. .