Materials Science: What do fire-fighting suits rely on to “avoid fire”?

There is a saying that “water and fire have no mercy.” Whether it is floods or fires, the harm they bring is something that the human body cannot directly bear. But for firefighters, dangerous flames are what they must deal with in their work. Therefore, in order to protect themselves, important protective equipment such as “firefighting suits” is absolutely indispensable.

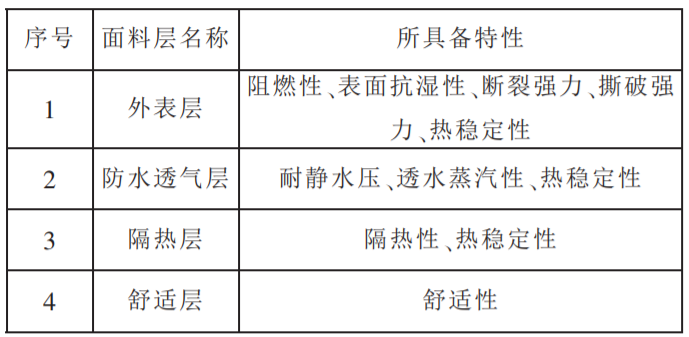

A qualified fire-fighting fire escape suit needs to ensure that firefighters have the ability to cross the fire scene within 8-10 minutes of rescue under high-temperature open flame conditions, and can keep the surface temperature of the human skin below 44°C. In order to have this ability, fire-fighting suits generally have a multi-layer structure, and each layer has its own function. It can be mainly divided into an outer layer, a waterproof and breathable layer, an insulation layer and a comfort layer. The name of each layer of fabric and the required properties can be seen in the table below – obviously, the first three layers are the most critical part.

Basic structure of firefighting suits and list of required characteristics of each layer

01

Choice of outer fabric

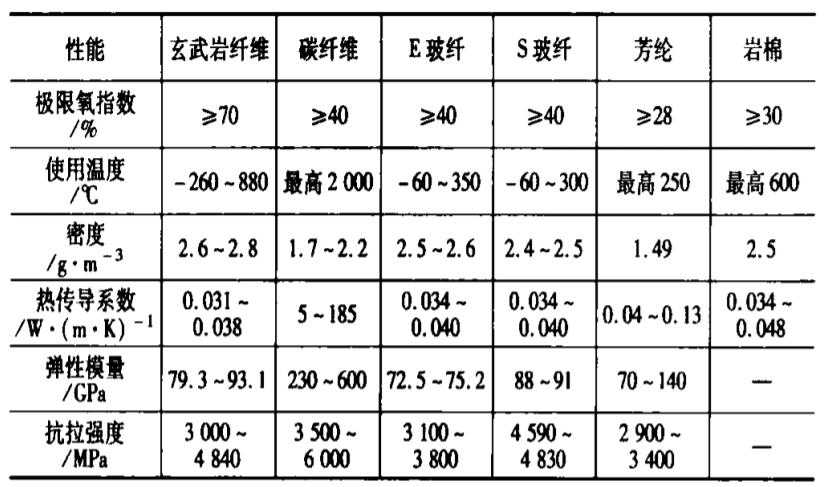

The outer layer of the fire-fighting suit is the layer in direct contact with fire and heat. Its function is to resist external fire or heat without damaging the overall protective function of the fire-fighting suit, that is, fire prevention and heat insulation. Therefore, high-temperature-resistant fibers are often used. Made of fabrics, mainly basalt fiber, carbon fiber, high silica glass fiber, etc.

02

Selection of waterproof and breathable fabrics

The waterproof and breathable layer is close to the flame-retardant layer fabric, which acts as a waterproof and prevents the penetration of steam and harmful chemicals. At the same time, firefighters move a lot and sweat a lot when fighting fires. Therefore, while meeting the waterproof requirements, fire fighters must also be moisture vapor permeable so that sweat can be discharged in time.

PTFE hydrophobic fiber

MiaoTian, ZhaoliWang and others established single-layer and multi-layer fabric models through simplified three-dimensional models, studied the temperatures of each layer and the skin surface under flash fire conditions, and found that in the multi-layer fabric system of firefighting clothing, it is waterproof and breathable. Layer is the most effective protective layer. At present, waterproof and breathable layers are mostly made of membrane + flame-retardant base fabric/cotton cloth. The most common ones are PTFE membrane, PE membrane, etc.

03

Selection of insulation layer fabric

The main function of the thermal insulation layer is thermal insulation, which maintains the firefighter’s own temperature and prevents damage to him from the high temperature outside. The thermal insulation layer plays an important role in the comprehensive thermal protection performance of the multi-layer fabric. The thermal insulation layer is mostly made of needle-punched felt made of high-temperature-resistant fibers through a needle-punching process. Commonly used ones include aramid needle-punched felt.

However, with the continuous development of firefighting suit research, people’s requirements for the functions of firefighting suits are also constantly increasing, and the materials used in firefighting suits are also quietly changing. In recent years, researchers have explored a variety of ways to improve the thermal insulation effect of materials, among which aerogels and hollow microbeads are more reliable.

①Aerogel insulation material

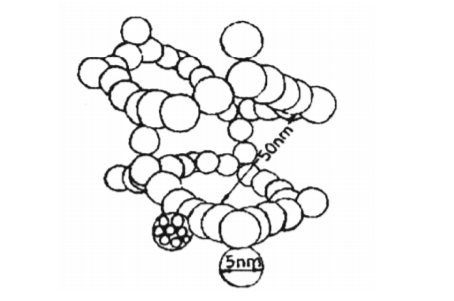

The special mesoporous and microporous structure of aerogel retains more air, giving it a very small thermal conductivity. It can effectively protect against thermal radiation at room temperature, but when the temperature rises, its thermal insulation performance decreases. In order to improve its thermal protection performance at high temperatures, 10% sunscreen agent is usually added. Due to the low mechanical strength of this type of material, fiber reinforcements generally need to be added or integrated into the fabric in the form of thermal insulation additives. The graphene sponge prepared by Jing Wei of Harbin Institute of Technology has a porosity of 99.7% and a thermal conductivity close to 0.023W/m-K of air. It is an efficient thermal insulation material with excellent high temperature resistance.

Airgel microstructure

②Hollow glass beads thermal insulation material

Liu Xin prepared aluminum titanate materials with low thermal expansion rates into aluminum titanate hollow microspheres. Combining the high temperature resistance of aluminum titanate with the thermal insulation properties of the structure of the hollow microspheres, a thermal insulation material with good performance was obtained. Material. Jin Tao and others found through experimental research that the larger the particle size of the hollow glass microspheres, the worse the heat insulation effect. Zhang Hui et al. added different types of hollow glass beads into the coating to improve the weaving effect.The fabric was coated and the experimental results showed that when the quality is the same, the smaller the diameter of the glass beads, the better the thermal protection performance of the composite fabric.

04

Summary

The functional design of firefighting suits has always been a hot research topic among scholars at home and abroad. It is expected that more new intelligent materials will be put into use in the future, such as phase change materials, aerogel materials, shape memory alloy materials, etc. Maximizing the advantages of these materials through humanized design and providing better thermal protection performance for firefighters will definitely be the future development model of firefighting clothing.