What are the classifications of flame retardant fabrics? How much do you know about the specific standards?

Classification of Flame-retardant fabrics

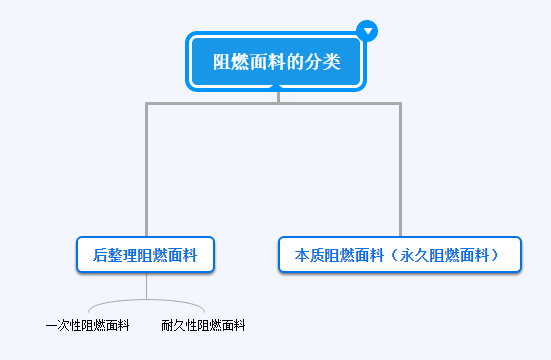

1. Classification based on material processing methods

Flame-retardant fabrics can be divided into intrinsic flame-retardant fabrics (permanent flame-retardant fabrics) and post-finished flame-retardant fabrics according to processing methods.

Intrinsic flame retardant fabrics are also called permanent flame retardant fabrics. They are formed by weaving flame retardant fibers and then dyeing and finishing. Flame retardants are added to the flame retardant fibers during the drawing process and are fused with the fibers. No matter how many times they are washed, Its flame retardant effect remains unchanged.

Finished flame-retardant fabrics are produced through coatings and additives during dyeing and finishing. The flame-retardant effect will gradually weaken after washing. They are generally used to produce things that are not washed frequently.

The cost of post-treatment flame retardant is lower, but the cost of flame retardant fiber is higher, and the permanent flame retardant fabric must be woven with 100% flame retardant fiber and cannot be interwoven with other fibers.

Since the concept of washing is mentioned in the “Finishing Flame Retardant Fabrics” above, it is conceivable that it can be classified again according to the number of times of washing.

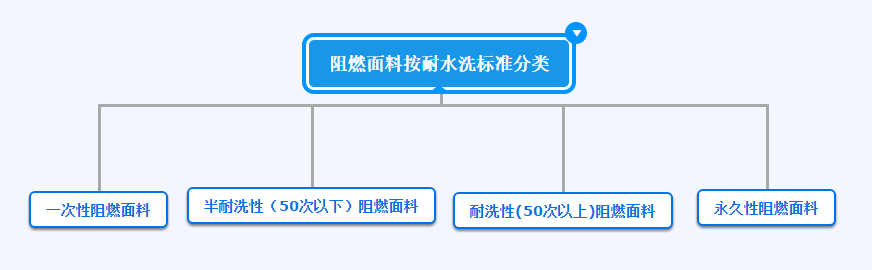

2. Classified according to washability standards

As shown in the figure above, flame retardant fabrics can be divided into disposable flame retardant fabrics, semi-washable flame retardant fabrics, washable flame retardant fabrics (that is, they can be washed more than 50 times) and permanent flame retardant fabrics according to whether they are washable or not. .

3. Classification according to ingredient content

Flame-retardant fabrics have different classification standards according to different component contents, including aramid flame-retardant fabrics, ecological flame-retardant fabrics, cotton flame-retardant fabrics, CVC flame-retardant fabrics and nylon flame-retardant fabrics, and the functions are also classified into different categories. Different, including anti-static, anti-acid and alkali and anti-oil flame retardant fabrics.

Introduction to flame retardant fabric standards

Flame-retardant fabrics require professional testing institutions to conduct special testing on the produced fabrics, and testing institutions such as SGS, ITS and other National Labor and Social Security Centers need to conduct very professional performance and fabric testing for flame-retardant fabrics. Only those that pass the test Only products can be safely put on the market.

1.GB8965-98–China National Standard for Flame Retardant Clothing

In 1998, the National Bureau of Standards of China promulgated industrial flame-retardant fabric clothing standards with reference to its standard of the same name and echoing similar international standards. It made very detailed provisions on many aspects of flame-retardant fabrics, including the overall quality of flame-retardant clothing. Performance, flame retardant properties of clothing materials and stitching, mechanical properties of clothing, structural design and processing of clothing, as well as finished product marking, packaging, transportation and inspection methods, etc.

2.GA10-91–Performance requirements and test methods for ordinary protective clothing for Chinese firefighters

my country’s Ministry of Public Security has issued testing standards for ordinary protective clothing for fire fighters. The regulations include the overall performance of flame-retardant clothing, the flame-retardant properties of stitching and clothing, the mechanical properties of clothing, the structural design and processing of clothing, Finished product marking and packaging transportation and inspection methods, etc.

3.EN531–EU industrial thermal protective clothing standard

In this standard�The overall performance, structural design, dimensional stability, flame spread, heat and melting metal resistance, size markings and marks, user information and identification patterns of flame-retardant fabric clothing are specified in detail.

4.EN479–EU fire protective clothing standard

This standard stipulates the standards for protective clothing for structural fire protection. It mainly cares and tests the protection performance against heat and flame. This standard does not include cleaning up chemical spills, forest fires, very close firefighting and road accidents. Special tasks such as rescue and special fire protection are required. These testing standards include general and additional requirements, important safety requirements, marking marks, user information and identification patterns.

5.EN479–EU fire protective clothing standard

The American Fire Protection Association stipulates the following aspects of industrial flash fire flame-retardant protective clothing: product marking, user information, clothing design, fibers, sutures, accessories, and labels.

6.NFPA19771998 version of the American Fire Protection Association fire clothing standard

NFPA19771998 version of the American Fire Protection Association fire clothing standard

This standard specifies the minimum clothing requirements for wildland fire firefighters, including the design, performance, testing, and testing of clothing components and accessories (shirts, jackets, pants, helmets, hoods, shawls, gloves, shoes). , this version combines the contents of the original NFPA1971, 1972, 1973 and 1974, and can completely replace the latter.

7.AS4967-2002 Australian (transitional version) fire protective clothing standard

The standard specifies the design requirements, proofing and pretreatment, thermal performance requirements, mechanical performance requirements, ergonomics and comfort requirements, general requirements, manufacturer information and marking marks for firefighters’ clothing used to fight structural fires.