Glass fiber: significant growth attributes, supporting the green and low-carbon development of the building materials industry

Glass fiber: Significant growth attributes help the green and low-carbon development of the building materials industry

In recent years, the National Bureau of Statistics has included fiberglass and fiberglass products in the “Classification of Strategic Emerging Industries”. With policy support, my country’s fiberglass industry will develop rapidly. In the long run, the strengthening and transformation of infrastructure in the Middle East and Asia-Pacific will increase the demand for glass fiber by a large amount. As the global demand for glass fiber in glass fiber modified plastics, sports equipment, aerospace, etc. continues to grow, The fiberglass industry has an optimistic future.

Inorganic non-metallic materials with excellent performance

Glass fiber is an inorganic non-metallic material with excellent properties. It has many types. Its advantages are good insulation, strong heat resistance, good corrosion resistance and high mechanical strength. However, its disadvantages are brittleness and poor wear resistance. Glass fiber is usually used as reinforcing materials in composite materials, electrical insulation materials and thermal insulation materials, circuit substrates and other fields of the national economy.

Glass fiber is made from six kinds of ores such as pyrophyllite, quartz sand, limestone, dolomite, boronite and boronite as raw materials through high-temperature melting, drawing, winding, weaving and other processes. The diameter of its single filament is From a few microns to more than 20 microns, it is equivalent to 1/20-1/5 of a hair. Each fiber strand is composed of hundreds or even thousands of single filaments. Glass fibers can be divided into continuous fibers, fixed-length fibers and glass wool according to shape and length; according to glass composition, they can be divided into alkali-free, chemical-resistant, high-alkali, medium-alkali, high-strength, high elastic modulus and alkali-resistant ( Alkali-resistant) glass fiber, etc.

Leading companies have obvious advantages

Glass fiber is a new material industry that the country encourages the development of. In recent years, domestic glass fiber production has maintained growth, and my country has become a major producer of glass fiber. According to statistics from the China Glass Fiber Industry Association, in 2012, my country’s total output of glass fiber yarn was 2.88 million tons (of which the output of pool yarn was 2.52 million tons); in 2021, the total output of glass fiber yarn was 6.24 million tons (of which the output of pool yarn was 5.80 million tons) million tons), the industry-wide main business revenue reached 124.4 billion yuan. In the past ten years, the fiberglass industry has entered a new stage of development from large to strong.

The main barriers to the glass fiber industry are reflected in policy, capital, technology and other aspects. The industry has high entry barriers and concentrated market supply. At present, a virtuous cycle has been formed for leading enterprises: the lower the cost, the higher the profit margin of enterprises. Excess returns are conducive to reducing corporate debt, refinancing, technology upgrading, and production capacity expansion, thereby further reducing costs and occupying a larger market share. Therefore, the overall pattern of my country’s fiberglass industry is relatively stable.

The scale effect of the leaders in the glass fiber industry is obvious, but each has its own focus, forming differentiated positioning in different segments. For example, China Jushi’s roving production capacity ranks first in the world, China Jushi and Taishan Glass Fiber have obvious advantages in the field of wind power yarns, Guangyuan New Materials, Honghe Technology, and Kunshan are in the leading position in the field of electronic yarn/cloth, and Changhai Co., Ltd. occupies the leading position in glass fiber composite materials. Main markets in the field.

Widely used in building materials, wind power and other fields

At present, the world’s fiberglass industry has formed a complete industrial chain from fiberglass, fiberglass products to fiberglass composite materials. Its upstream industries involve mining, chemical industry, and energy, and its downstream industries involve building materials, electronic appliances, rail transit, petrochemicals, Traditional industrial fields such as automobile manufacturing and emerging fields such as aerospace, wind power generation, filtration and dust removal, environmental engineering, and ocean engineering.

1. Building materials field

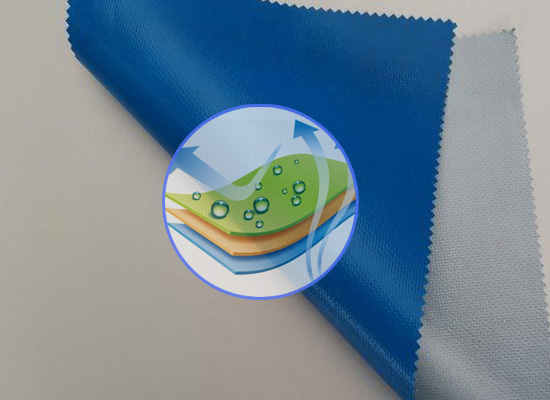

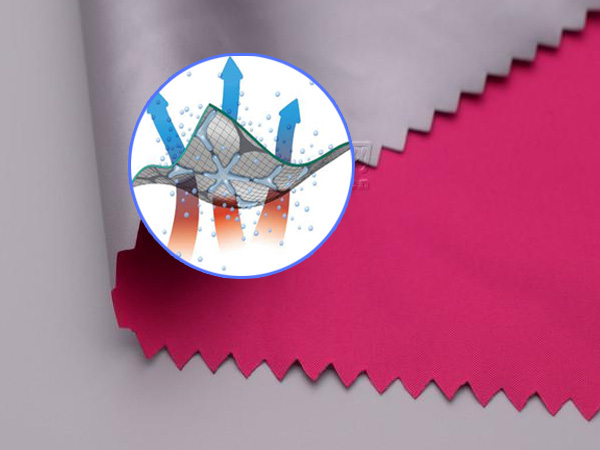

Among the downstream demands for glass fiber, the building materials field has the largest demand for glass fiber. Glass fiber is mainly used in GRC boards, insulation boards, fireproof boards, sound-absorbing materials, load-bearing components, roof waterproofing, membrane structures, etc. in the building materials industry, involving various scenarios such as building load-bearing, reinforcement, decoration, waterproofing, insulation, sound insulation, and fire protection. In the GRC production process, glass fiber helps to enhance the solidity of the gypsum block and prevent the gypsum from falling apart after solidification; glass fiber has excellent electrical insulation and can be used for thermal insulation materials and fire protection shielding materials; glass fiber can be melted into glass at high temperatures Shape beads, in line with the requirements of fire prevention and control in the construction industry; the combination of glass fiber and gypsum can achieve good sound insulation effects.

With the further advancement of the “double carbon” policy, the good performance of glass fiber in terms of thermal insulation, heat insulation, pressure resistance, and sound insulation can effectively improve the performance of green buildings, reduce building energy consumption, and effectively promote the green and low-carbon development of the building materials industry.

2. Wind power field

As the wind curtailment rate in various provinces gradually declines, in order to reduce carbon emissions and achieve the medium- and long-term goals of carbon peaking and carbon neutrality, wind power and photovoltaic power gradually replace thermal power is a long-term trend, which will provide impetus for the growth of glass fiber demand. As domestic blade manufacturers gradually break the foreign monopoly, upstream fiberglass companies have created more demand from domestic applications; at the same time, as the trend of large-scale wind turbine blades begins, high-modulus and high-strength glass fiber is developed, or glass fiber is used in composite with carbon fiber. Main technical routes.

3. Integrated circuit field

Electronic yarn is a high-end product among fiberglass yarns. The diameter of the single filament does not exceed 9 microns. It is mainly used to weave electronic cloth as the basic material of copper clad laminates and printed circuit boards; electronic yarn, electronic cloth, copper clad laminates and printed circuit boards constitute The upstream and downstream basic materials industries are closely connected in the electronic circuit industry chain. According to data from the China Fiberglass Industry Association, during the “14th Five-Year Plan” period, the market demand for copper-clad laminates is expected to maintain a year-on-year growth rate of about 3 points higher than the national GDP in the current period; driven by the growth of the copper-clad laminate industry, the overall electronic cloth Demand shows an upward trend.

4. New energy vehicle field

According to data from the China Fiber Composites Network, the transportation sector accounts for approximately 14% of my country’s glass fiber consumption and is an important application scenario for glass fiber. Glass fiber has excellent performance and has obvious advantages over traditional materials. my country’s automobile industry mainly uses this material for covering parts and stress-bearing components, such as roofs, window frames, bumpers, fenders, body panels and instrument panels. The railway transportation industry is mainly used for the inner and outer panels, ceilings, seats and SMC window frames of carriages. The shipbuilding industry is used to manufacture various fast passenger ships, fishing boats, tour boats, as well as various passenger ships, lifeboats, etc.