Authentic flame retardant yarn manufacturer? Flame retardant polyester yarn, flame retardant acrylic yarn, flame retardant acrylic cotton yarn, free samples

Flame-retardant acrylic yarn has obvious flame-retardant effect. It burns without open flame and extinguishes automatically. It is widely used in textiles, home textiles, curtains, carpets, seat cushions, webbing and other fields. It is an ideal raw material for the production of flame-retardant fabrics and blankets. Various specifications and ratios can be customized according to customer requirements. Flame-retardant yarn is a special fabric that can delay flame burning. It is mainly used to make protective clothing and special functional products. Clothing and industrial fabrics are widely used in fire protection, clothing, petroleum, electric power, natural gas, metallurgy, machinery, mining, chemical industry, coal, shipping and other industries.

Flame-retardant polyester yarn is copolymerized and flame-retardant modified, such as using tetrabromobisphenol A hydroxyethyl ether or phosphorus-containing compounds as comonomers, and obtained by transesterification and polycondensation with dimethyl terephthalate and ethylene glycol. copolymer. It is then made by melt spinning and drawing; it is blended with flame retardant modification, adding a phosphorus-containing compound or a halogen-antimony composite flame retardant to the spinning melt, and then made by melt spinning and drawing;

Or use composite spinning components to add flame retardant to the core layer, and the skin layer is ordinary polyester. It is suitable for making flame-retardant protective clothing in metallurgy, machinery, forestry, fire-fighting and other industries. It can also be used as decorative cloth in hotels, guesthouses, opera halls and theaters. Flame retardant yarn is a special fabric that can delay flame burning. It is mainly used to make protective clothing, special performance clothing, and industrial fabrics. It is widely used in fire protection, clothing, stores, metallurgy, machinery, mining, and chemical industry.

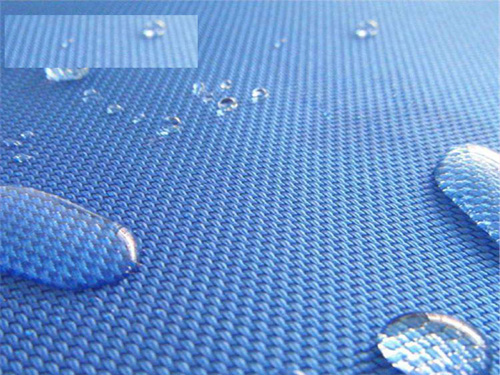

In the past ten years, the functional textile market has developed rapidly, and functional fabrics with various unique selling points have emerged one after another. In addition to satisfying the basic functions of covering up ugliness and beautifying the market, textiles, especially functional textiles, are constantly expanding their functional added value. For example: waterproof fabrics, flame retardant fabrics, antibacterial fabrics, scented fabrics, anti-mosquito fabrics, thermal storage and thermal fabrics, etc. Not only can it be used in various general consumer fields, but it can also be used in various walks of life, such as life, industry, medical care, military, transportation, etc. The market potential is huge.

Among the many functions of textile fabrics, many of them require separate processing. The simultaneous use of two or more functional additives will most likely cause various defects and problems due to compatibility and physical and chemical properties. The more common defects include: precipitation, oil drift, delamination, blistering, incompatibility, spots, color flowers, sediments and other conflict problems. But at the same time, due to the improvement of environmental protection and energy saving thresholds, the processing of multiple additives in the same bath is a major trend in the future. The same-bath finishing with multiple additives can significantly save production costs and time costs for printing and dyeing enterprises. In this issue, we mainly screen and analyze the application cases of “waterproof + flame retardant” two-in-one finishing.