What is fire retardant wall covering? The composition of fire-retardant wall coverings

What is it? The composition of fire-retardant wall coverings

What is it? The composition of fire-retardant wall coverings

The use, packaging, storage and transportation of mining dryers

Mine hair dryer

Purpose: Flexible pipes used in coal mines, tunnels, subway projects, and underground to guide wind flow in a certain direction

Category: positive pressure air duct, negative pressure air duct; three-ventilation duct

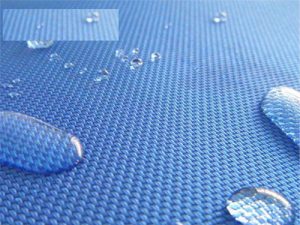

Variety and material: According to the coating material, the hair dryer is divided into rubber-coated cloth hair dryer and plastic-coated cloth.

Negative pressure air ducts and rubber-coated cloth air ducts are anti-static and flame-retardant. Production implementation standards: Standard number, MT164-2007 standard Huai, Standard number: MT165-2007 standard Huai. Rubber or plastic-coated fabric air ducts specify the classification, structure, technical requirements, test methods, inspection rules, packaging, marking, transportation and storage of rubber or plastic-coated fabric air ducts.

Firefighting clothing

Firefighting clothing

Packaging, storage and transportation

1. Compress the hairdryer along the axial direction to less than 700mm in length, fix it in 3 to 4 places with ropes or cloth strips, and then package it with materials with good wear resistance.

2. During transportation, the hairdryer must be protected from mechanical impact and friction, as well as sunlight and rain.

3. The product should be stored in a well-ventilated warehouse, and the code should not be too high to avoid affecting the quality of use. Used air ducts should be cleaned and dried first, then folded and stored. It is forbidden to come into contact with substances that damage the quality of rubber and plastic. Avoid direct sunlight and rain. The storage temperature should be -15℃~35℃, the relative temperature should be 45-75﹪ and it should be 1m away from the heat source.

4. When the product is transported and stored under specified conditions, its flame retardancy and antistatic properties shall comply with the provisions of this standard within one year from the date of production.

5. The air guide duct should be of appropriate specifications and elbows, tees and other special-shaped specifications according to the requirements of the tunnel and fan air volume. Pay attention to the direction of air flow when connecting.

Fireproof cloth

Fireproof cloth

6. It should be hung in the tunnel to keep it straight, tightened and hung firmly. It must be hung at every loop and repaired when it is damaged. It must be turned slowly in order to reduce resistance and eliminate accumulated water.