Aramid Industry Overview

Aramid IndustryOverview

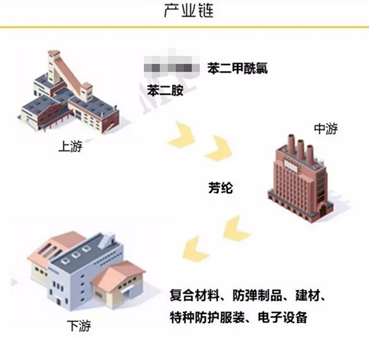

1. Introduction to aramid

Aramid refers to a high-tech synthetic fiber made from aromatic compounds as raw materials through polycondensation spinning. Its full name is aromatic polyamide fiber. In 1974, the United States Trade Federation named it “Aramid fiber”, referred to as AF. Its definition is: at least 85% of the amide bonds (-CONH-) are directly connected to the carbon atoms in the two benzene rings. Aramid, carbon fiber, and ultra-high molecular weight polyethylene fiber are collectively known as the world’s three largest high-performance fibers.

Aramid fiber has excellent properties such as light weight, flame retardant, temperature resistance, insulation, radiation resistance, high strength, and high elastic modulus; it is widely used in military and national defense, security protection, aerospace, environmental protection, electronic and electrical materials and other fields.

(1) Classification of aramid fiber

At present, the main products that achieve industrial production are meta-aramid (aramid 1313) and para-aramid (aramid 1414). The molecule of meta-aramid (aramid 1313) is a zigzag linear macromolecule composed of amide groups connected to meta-phenyl groups. In its crystal, hydrogen bonds exist on two planes, arranged like a lattice, thus forming a three-dimensional structure of hydrogen bridges; the macromolecular structure of para-aramid (aramid 1414) is an amide bond connected to the benzene ring. bit, forming a nearly rigid linear structure, which is a main chain polymer liquid crystal polymer. The chemical structures of the two are similar, but their properties are quite different and their application fields are different.

Meta-aramid has outstanding high temperature resistance, flame retardancy and insulation, and is mainly used in fields such as high-temperature protective clothing, electrical insulation and high-temperature filtration. Para-aramid has the characteristics of high strength and high modulus, and is mainly used in personal protection, bulletproof armor, mechanical rubber products, high-strength cables, asbestos substitutes, etc.

1. Meta-aramid

The full name of meta-aramid fiber is poly-m-phenylene isophthalamide fiber, commonly known as aramid 1313. It is known as “fireproof fiber”. It is an organic high-temperature resistant flame-retardant fiber with excellent comprehensive properties. It is a thermally stable fiber. High-performance fiber materials with high flame retardancy and good electrical insulation are widely used in fields such as safety protection, environmental protection and modern industry.

In the field of safety protection, protective clothing, protective gloves and other safety equipment made of meta-aramid can effectively resist high temperatures, flames, arcs and other operational injuries, and protect workers’ safety to the maximum extent. They are widely used in the military, firefighting, petroleum, etc. Electric power, forestry and other fields;

In the field of environmental protection, meta-aramid can be processed into needle-punched non-woven fabrics and woven filter fabrics, which are widely used in high-temperature flue gas filtration in cement, steel, road construction and other industries. The dust removal efficiency reaches 99.99%, which can greatly reduce air pollution. Emission of pollutants to achieve environmental protection, green and sustainable development;

In the field of modern industry, meta-aramid fiber is widely used in various types of high-temperature transportation equipment, power transmission equipment, electrical insulation equipment and other industrial production fields due to its temperature resistance, flame retardancy, insulation and other properties. It is an important component of modern manufacturing industry. Basic and key materials.

Meta-aramid chemical structural formula:

2. Para-aramid

The full name of para-aramid fiber is poly-p-phenylene terephthalamide fiber, commonly known as aramid 1414. It is known as “bulletproof fiber” and is one of the high-performance fibers with the largest output and the most widely used in the world today. In the field of automobile industry, para-aramid is an indispensable skeleton reinforcement material in automobile hoses, tires, and timing belts. It is an important environmentally friendly reinforced wear-resistant material in brake pads and clutch plates, especially environmentally friendly turbocharged vehicles. The application of aramid is irreplaceable; in the field of information and communication, the application of para-aramid has greatly promoted the development of the communication industry. Para-aramid is now used in almost all optical fiber cables, new mobile phone batteries and other information and communications products, which play an important role in accelerating the modernization of communications.

(2) The development history of aramid fiber

(3) Main performance characteristics of aramid fiber

Aramid fiber has excellent properties such as light weight, flame retardant, temperature resistance, insulation, radiation resistance, high strength, and high elastic modulus; it is widely used in military and national defense, security protection, aerospace, environmental protection, electronic and electrical materials and other fields.

1. Mechanical properties

The most significant characteristics of para-aramid are high strength and high modulus. Its strength is greater than 25 g/den, which is 5 to 6 times that of high-quality steel, 3 times that of glass fiber, and 2 times that of high-strength nylon industrial yarn; its modulus is It is 2 to 3 times that of high-quality steel or glass fiber, 10 times that of high-strength nylon industrial wire, and its toughness is 2 times that of steel wire. In addition, aramid fiber is light in weight, its weight is only about 1/5 of steel wire.

Comparison of properties between para-aramid and other high-strength fibers

2. Heat resistance

Aramid fiber has long-term thermal stability. Aramid 1313 has almost no loss of strength at 130°C. It can be used at 220°C for more than ten years. At 260°C for 100 hours, the mechanical strength still maintains 65% of the original value at 400°C. Begins to carbonize without melting. The heat resistance of aramid 1414 is better than that of aramid 1313. The shrinkage rate at 150°C is 0 and it does not decompose or melt at a high temperature of 560°C. The strength and modulus of nylon and polyester decrease as the temperature increases.

Automotive industry applications

Para-aramid has the characteristics of high strength and modulus, low density and creep resistance, so it is often used as a reinforcing material to support optical fibers and cables, and to protect optical fibers and cable guide cores from shaft damage caused by overload. to strain. The non-flammability of fiber also plays a certain role in fire protection during the use of cables. Therefore, para-aramid fibers are widely used in reinforcing parts of indoor and outdoor optical fibers and power cables, playing an important role in promoting the development of my country’s new generation of communication technology.

In July 2012, my country upgraded the broadband upgrade project to a national strategy, namely the “Broadband China” strategy. In the following years, the length of new optical cables and the output of optical cables in my country increased rapidly, driving demand for para-aramid. In recent years, with the popularization of broadband to households and the retreat of the 4G construction tide, my country’s optical cable output and new length have slowed down. At present, the domestic consumption of para-aramid for optical fiber protection enhancement is about 4-5 thousand tons, the supply of domestic enterprises is about 6-7 hundred tons, and the stock replacement space is more than 3,000 tons. As 2019 is the first year of 5G, capital expenditures for 5G construction will gradually increase in the future, which is expected to re-drive demand for optical cables, and the consumption of para-aramid fiber for optical fiber enhancement and protection will also further increase.

Para-aramid is also suitable as a reinforcement for tire radials and other rubber products. Aramid-reinforced tires have high driving speed, controllability and comfort. They can also reduce body weight, reduce rolling friction and driving noise, reduce “out-of-plane bending stiffness”, reduce rolling friction, reduce fuel consumption, and are energy-saving. , low noise and long life characteristics. At present, international tire manufacturers such as Goodyear, Michelin, Pirelli, and Bridgestone have commercialized para-aramid reinforced tires for various high-end models. Domestic Wanli Tire, Qingdao Senqilin and Doublestar Tire have carried out the research and development of para-aramid reinforced passenger tires, while Linglong Tire, Triangle Tire and Shuangqian Tire have carried out the research and development and production of para-aramid reinforced load-carrying radial tires. In addition, the knitting (or braiding) process is used to process the twisted aramid yarn into mesh cloth, and then compound it with rubber. It is now widely used in automotive hoses, such as cooling water pipes, fuel pipes, brake pipes, especially turbochargers. Tube. Representative domestic automotive hose companies include Meichen Ecology, Anhui Zhongding, Tianjin Penngling, Zhejiang Junhe, etc. Aramid hoses have been supplied to major car manufacturers such as Volkswagen, General Motors, and Chery.

Commercial para-aramid reinforced tire applications

Globally, the consumption of vehicle friction materials and rubber reinforcement materials is about 30,000 tons. Due to the constraints of fiber raw materials and the gap between the domestic development of the automobile industry and overseas, the application of this field is still in its infancy. In 2018, my country produced about 27.8 million automobiles, accounting for about 30% of the world. It is the largest automobile producer and consumer, and the para-aramid fiber market has great potential in the future.

3. Market price of para-aramid fiber

The demand for para-aramid is strong and the price has risen sharply. Especially in 2018, due to increasingly stringent domestic environmental protection requirements, the supply of domestic para-aramid production raw materials was tight. In addition, during the same period, the US military started to replace individual weapons and equipment, including camouflage uniforms, helmets, combat boots, combat vests, etc. Individual soldier equipment, therefore, DuPont products give priority to ensuring supply from the United States. The domestic supply gap increases, causing the average product price to rise from approximately 155,000 yuan/ton in 2017 to approximately 235,000 yuan/ton, a year-on-year increase of 51.6%. In 2019, the price of para-aramid fiber was overall stable, with the average price remaining at 220,000-240,000 yuan/ton.

Para-aramid fiber prices continue to rise (10,000 yuan/ton)

Since para-aramid has important application attributes in the military field, and domestic technology lags behind overseas companies, para-aramid is one of the new materials that has been supported by long-term policies, and there is a strong demand for localized substitution. Domestic para-aramid fiber is 80% dependent on imports, mainly from companies such as the United States and Japan. In recent years, the uncertainty of the global trade environment has increased, and high-end and sensitive application fields such as military industry are easily restricted by overseas companies. Therefore, there is a need for localized substitution. More and more urgent.

The distribution of para-aramid fiber application fields in my country is shown in the figure below:

Para-aramid fiber in my country is mainly used in fields such as optical fiber, rope and rubber reinforcement. However, there are fewer aramid products used in high-end bulletproof fields such as national defense and military industry. Taking 2014 as an example, the actual supply of para-aramid fiber in my country was around 1,000 tons, which was mainly used in lower-end fields such as high-temperature materials, friction materials, and cables. Most domestic downstream para-aramid fiber manufacturers still rely on imports.

The global consumption of para-aramid fiber is about 80,000 tons, and the domestic consumption is about 10,000 tons. It is mainly used in fields such as safety protection, automotive friction materials, and optical fiber protection enhancement. Para-aramid production process barriers are high. DuPont of the United States and Teijin of Japan occupy about 70% of the global share, and more than 80% of domestic production relies on imports. As para-aramid has important applications in fields such as national defense and military industry, and the uncertainty of the global trade environment has increased, and sensitive application fields are susceptible to overseas restrictions, the demand for local substitution of para-aramid has become increasingly urgent. (Shen Wanhongyuan)

Summarize

In summary, the application of aramid fiber in the domestic market is still in a relatively low-end and narrow field, and the high-end protection field is still in the development stage. However, with the gradual improvement of protection requirements in the military and defense fields, industrial production fields, and civilian fields , the demand in the domestic market will increase tremendously, even in the military and police combat training uniform market, there is a demand of tens of thousands of tons every year.