Production practice of fire-resistant acrylic yarn

Production Practice of Fireproof Acrylic Yarn

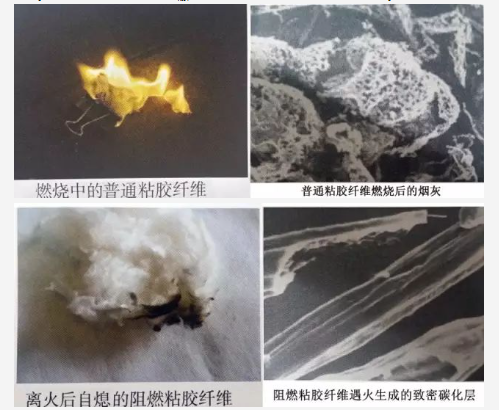

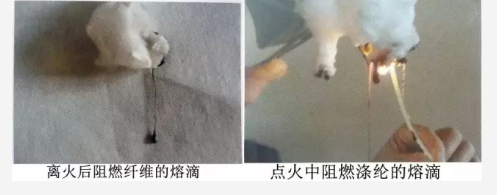

Fire-resistant acrylic fiber is a functional fiber with fire-resistant properties developed after flame-retardant acrylic fiber. It is widely used in clothing, home furnishings, decoration, non-woven fabrics and fillers, etc. Our company has carried out technical research and adjustments on the pretreatment and health care of this raw material, and carried out technical research and adjustments on the temperature and humidity of each process and production process workshop, solving a series of bottlenecks that restricted the normal production, and successfully spun 100% fire-resistant acrylic yarn. Quality quality has been recognized by customers.

1

Raw material characteristics

The average length of fire-resistant acrylic fiber is 51mm, but there are 70-80mm long fibers, the fineness is 1.1dtex, the breaking strength is 2.59cN/dtex, and the elongation is 20.1%. Compared with ordinary acrylic fiber, the strength and elongation are reduced to varying degrees.

2

Raw material handling

The moisture regain of the raw material is 10.4%, the fibers are much curled, and the hand feels astringent and rough. Before production, it is necessary to spray antistatic agent and water for health treatment to increase the spinnability. After spraying with a solution prepared with 15% water and 0.5% antistatic agent, it is placed in the health room and simmered for 48 hours. The temperature of the health room is required to be controlled at 30°C. When spraying the solution, it is manually spread layer by layer to ensure uniform adsorption of fibers, so that the moisture regain rate of the raw materials reaches about 15-20% when put on the machine.

3

Spinning process

The cured fireproof acrylic fiber has been dehumidifying since it was put into production. Therefore, a special production line needs to be pulled out before going on the machine. All process machines are individually enclosed with isolation cloths, and methods such as ground water sprinkling and warm water spraying are used to ensure the humidity in the workshop. High control. Semi-finished products such as cotton laps, raw slivers, drawing slivers, rovings, and spun yarns should be wrapped in plastic bags promptly after coming off the machine to minimize moisture loss.

3.1 Opening and cleaning process

The opening and cleaning process adopts the process principle of “grasping frequently and less, loosening more and beating less, combing instead of beating, and reducing cotton waste”. It appropriately reduces the speed of the combing roller beater, reduces the spacing between dust rods, and increases the distance between the combing roller beater and the dust. The spacing between rods is to reduce fiber damage and reduce the amount of waste. The main process parameters of opening and cleaning cotton: the speed of each beater is appropriately reduced, the speed of the carding roller is reduced from 650r/min to 550r/min, and the speed of the cotton picking beater is reduced from 720r/min. Reduce it to 650r/min, increase the pressure of the pressing roller, and install a hanging spindle above the rolling machine. The roving strip and the cotton roll are wound simultaneously to facilitate the stratification of the cotton roll and prevent the roll from sticking during unwinding. Control the inventory of cotton rolls and wrap all spare rolls in plastic bags to prevent moisture loss.

3.2 Carding process

Carding adopts the process principle of “reducing blows and moderate carding”. Appropriately adjust the thorn ratio between the cylinder and the thorn stick, appropriately reduce the rotation speed of the lick-in roller, and enlarge the distance between the lick-in roller and the cotton feeding plate to reduce fiber damage; appropriately reduce the distance between the cover plate and the cylinder to enhance carding of the fibers. Appropriately reduce the sliver dispensing speed to 50m/min, and the sliver sliver quantity is 20.5g/5m. The carding machine is individually isolated and humidified, and the relative humidity is adjusted from the original 55-60% to 60-70%. The measured card sliver quality indicators: weight unevenness 4.0%, sliver CV value 5.5%, and neps count 1/g.

3.3 Drawing process

The draw frame (JWF1312A) gauge is adjusted to 17*27mm. All the top rollers are treated with antistatic agent coating to reduce the sticking phenomenon caused by static electricity. A rubber roller with good anti-winding performance of suitable spinning chemical fiber is selected, and the upper sliver press cylinder is used. The eye number of the draw frame is fixed and the cans are used crosswise. The machine adopts isolation humidification. When changing cans in front of the machine, a plastic bag is placed in the can, and when the can is full, the bag is sealed to moisturize. Ensure that the relative humidity is about 70%, the vehicle speed is appropriately slowed down, and the dosage is 19.5g/5m. Measured quality indicators of cooked strips: weight unevenness 1.2%, dryness CV value 3.8%

3.4 Roving process

The machines are all isolated and humidified using nozzles. The twist of the rovings is reduced as much as possible while ensuring that the rovings are not disconnected, so as to reduce the phenomenon that the fine yarns cannot be stretched. The roving process adheres to the principles of “medium weight, medium pressure, medium spindle speed, and large roller distance”; control the tension and elongation of large, medium and small yarns; select rubber rollers with good anti-winding properties suitable for spinning chemical fibers, and use rubber rollers on the surface. Antistatic agent coating treatment; roving (FA1435) gauge adopts 16*30*32mm, basis weight 5.0g/10m. Measured roving quality indicators: weight unevenness 1.0%, evenness CV value 4.5%.

3.5 Spinning process

The relative humidity is adjusted from 53-58% to 60-65%. The preferred draft ratio in the back area is 1.6. Use a medium top roller pressure, a larger roller spacing in the back area, a low spindle speed, and a front top roller. The front punch is 3mm, and the length of the floating zone is 13mm; a rubber roller with a hardness of 72 degrees suitable for spinning and good anti-winding performance is selected, and the surface of the rubber roller is treated with an antistatic agent coating; an apron is selected that is suitable for spinning chemical fiber, anti-winding, and highly wear-resistant; spun yarn The spacer block is one size larger than the regular model. Measured bobbin quality index: 32Ne/1, weight unevenness 1.8%, evenness CV value 14.0%, (-50%) 0 details/km, (+50%) 20 thick places/km, (+200%) Neps 35/km.

3.6 Winding process

The bobbins are wound up in a timely manner after being unloaded from the machine. The process principles of ‘medium speed and medium tension’ are adopted to rationally set the yarn clearing process parameters to remove harmful defects. Ensure the consistency of process parameters of the same variety and different machines; the ratio of empty twist strength to original yarn strength should be greater than 80%; the good package rate on the machine is required to reach 99% and above; the actual measured package yarn quality index: 32S/1, the weight is not Uniformity 1.5%, evenness CV value 14.8%, (-50%) fine points 1/km, (+50%) thick places 22/km, (+200%) neps 38/km..Strength 230.5cN.

4

Conclusion

Through the production practice of spinning medium-long fiber fire-proof acrylic fiber on cotton spinning equipment, the processing of raw materials and the temperature and humidity of each process are key. After the raw materials are put on the machine, they must be pushed forward quickly and in a timely manner. The semi-finished products must prevent moisture loss and reduce the impact of static electricity to ensure their Spinnability.