What is “aramid paper”?

What is “aramid paper“?

This is a magical paper cloth. Place it together with A4 paper and light it with a lighter. The A4 paper has already burned, but it cannot be lit alive or dead.

Paper on the left and A4 paper on the right

Not only that, when I dropped 95% sulfuric acid on it, let it sit for 10 minutes, and then picked it up with tweezers, there was no change, but the cotton cloth next to it had been corroded through.

Sulfuric acid is difficult to corrode paper and cloth

Cotton cloth has been corroded

Next, boil the two fibers with caustic soda solution. After 30 minutes, their strength is tested. The paper cloth is obviously stronger than the cotton cloth.

Paper cloth is stronger

Cotton fabric breaks easily

And it is one of the world’s three major high-tech fibers – aramid.

What is aramid?

According to characteristics, aramid fiber can be divided into “bulletproof fiber” and “fireproof fiber”.

The former also has another name “Kevlar”. The strength is 5 to 6 times that of high-quality steel, the toughness is twice that of steel, and the weight is only 1/5 of steel. It is often used in body armor and bulletproof helmets.

Bulletproof test: the fabric was not penetrated

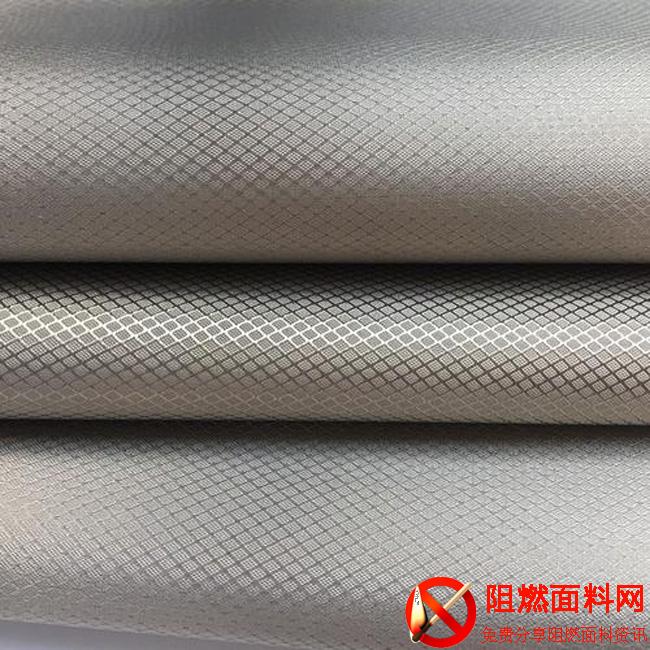

The latter’s name is “Nomex”. Its thermal stability, flame retardancy and electrical insulation are relatively strong, and the “aramid paper honeycomb” made with it has a wide range of uses. For example, the “sandwich structure” of an aircraft is like a sandwich. There is a layer of honeycomb composite material sandwiched between the two skins. It not only reduces the overall weight, but also increases the structural strength. It is used in the doors and bulkheads of the aircraft. , floor, ceiling, luggage rack, flaps, tail, radome and other positions are covered.

Monopolized aramid paper

The manufacturing technology of “aramid paper” has been monopolized by the United States, Japan and other countries for decades. The special-shaped parts made from it only cost 20 yuan each, but they can be sold in Japan for 2,800 yuan, and the number of units sold is entirely up to the other party. This feeling of being controlled by others is really uncomfortable, so at the end of the 20th century and the beginning of the 21st century, our country began research on aramid paper.

Because traditional papermaking methods are difficult to match with high-performance synthetic fibers, Professor Zhang Meiyun from Shaanxi University of Science and Technology studied polymer materials based on his papermaking major, and finally chose to “hot press molding” the fibers. After three years of running-in, Zhang Meiyun’s team provided 17 batches of samples to manufacturers and successfully gained industrial recognition. In 2017, this achievement also won the “Second Prize of the National Science and Technology Progress Award”.

In addition, the team led by Professor Hu Jian of South China University of Technology is also working hard on this road. In 2016, the aramid paper technology they developed was priced at 66.84 million yuan, and they built a joint venture with a company under the CRRC Corporation through technology shares. In 2019, the first batch of manufactured aramid paper was officially put into production.

Although there is still a certain gap in the performance of domestically produced aramid paper compared with imported aramid paper, now that the most difficult step has been taken, I believe that with the continuous development of science, the domestic replacement of aramid paper will be achieved in the future. !