Polychloropropyl fiber and polypropylene fiber

Polyvinyl fiber and polypropylene fiber

1. Cotton short fiber 1.65~2.75dtex (1.5~2.5 denier)

Knitwear: cotton sweaters and pants, jerseys and pants, knitted outerwear, etc.

2. Wool type short fiber 3.3~16.5dtex (3.0~15 denier)

(1) Blended with polyester, it can be made into wool-like mid-length fiber fabrics

(2) Acrylic blankets, wool, bedspreads, pillow covers, carpets, curtains

(3) Blended with wool, it can be made into yarn and blankets

(3) 9.9~16.5dtex (9~15 denier) can be used for artificial fur and carpets

3. Tops

Can be made into bulked velvet, knitted velvet, hats, scarves

4. Composite fiber

Acrylic fiber made from a composite of two or more components has a strong wool texture and can be used to make various yarns, blankets, carpets and other fabrics

Vinyl fiber

Part.5

1. Short fiber 1.5dtex (1.4D)×35mm

(1) 50% blend of vinylon fiber and cotton can be made into various clothing items

(2) Thin cotton blended fabrics can be made into underwear, bed sheets, mosquito nets, cotton sweaters, trousers, undershirts and other knitwear.

(3) Labor protection clothing, shoe uppers, shoelaces, etc.

(4) Pure vinylon canvas, transport belts, transport covers, military gun jackets, grain bags and other industrial cloths

2. Pull-cut yarn

(1) It has good seawater corrosion resistance and can be used for fishing nets and seaweed cultivation.

(2) Ropes suitable for offshore operations

3. Soluble fiber

The filament without acetal is interwoven with ramie or cotton, and after post-processing such as dimension reduction, the fabric is crisp, smooth, and has good hygroscopicity. It is a high-end product (such as linen handkerchiefs, etc.)

Polypropylene fiber

Part.6

1. Short fiber

(1) Blended with cotton, it can be made into fine cloth, sheets, gloves, and pants.

(2) Blend with viscose fiber to make blankets

(3) Polypropylene blankets and floors

(4) Polypropylene cotton batting, light and warm

2. Filament

(1) Polypropylene has a smaller specific gravity than water, is wear-resistant and corrosion-resistant, and can be used as ropes, fishing nets, etc.

(2) For industrial purposes, it can be used as canvas, hoses, packaging materials, filter cloth, and work clothes.

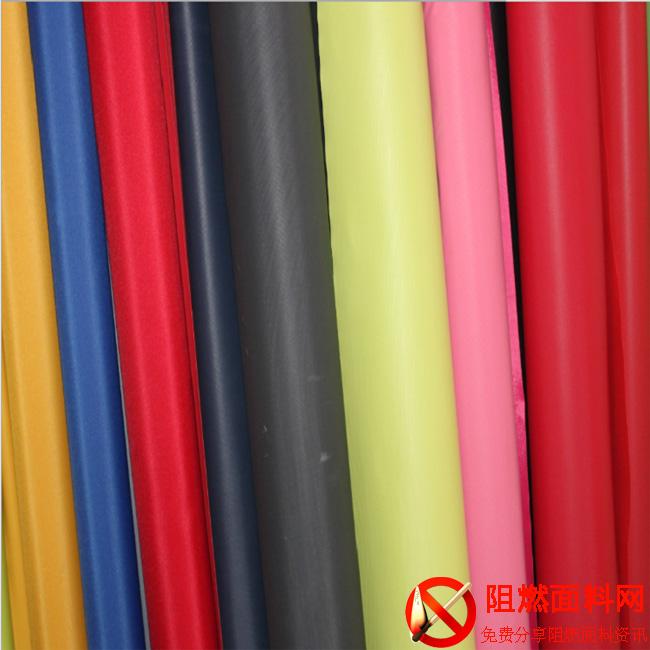

3. Colored fiber

Use colored masterbatch to spin colored polypropylene short fibers and filaments through melt spinning process. Use pure or blended fabrics to make various fabrics and decorative fabrics

spandex fiber

Part.7

1. Spandex naked silk

Can be used for knitting and other yarn interweaving, and can also be used for the waistband of pantyhose

2. Core-spun yarn

It uses spandex as the core thread and is wrapped with cotton, wool, acrylic and other fibers. The elastic elongation of core-spun yarn is 150%~200%. For example, the core-spun yarn obtained by wrapping two strands of 47.6dtex cotton yarn out of 156dtex spandex can be used to weave elastic denim, corduroy and three openings of knitwear (neckline, cuffs, hem), etc.

3. Covering yarn

It is made of spandex as the core yarn and wrapped with nylon elastic yarn or other fibers. The elastic elongation of the covered yarn is 300~400%. For example: 2170 type covered yarn, which is a covered yarn made of 233dtex spandex as the core yarn and outer 78dtex nylon elastic yarn. It can be used as a sock for elastic nylon socks. mouth

4. Combined twisted yarn (jointly twisted yarn)

It is made of 1 to 2 pieces of ordinary cotton yarn, wool yarn or nylon and spandex combined and twisted. It is often used to weave elastic labor cloth.

Characteristics and applications of Lyocell fiber

Part.8

Lyocell is a new, environmentally friendly fiber that is hailed as the “green fiber of the 21st century” by the international textile industry. Its excellent properties of natural fibers and synthetic fibers allow the product to combine the moisture absorption and breathability of cotton, the feel and luster of silk, the strength of chemical fibers, and the comfort of wool. Its great affinity with natural fibers enables the development of a variety of products. High value-added woven and knitted products have extremely broad market prospects.

Characteristics of Lyocell (Tencel short fiber, Newcell filament yarn) fiber and yarn:

1. It has excellent characteristics of cellulose fiber. Lyocell fiber fabric has a refreshing feel, good moisture absorption and breathability, and has the drape of silk. The touch can change from cotton to wool, silk, and various other feelings.

2. High strength. The dry strength of Lyocell fiber is close to that of polyester fiber, while the wet strength only decreases by 15%, which is far superior to viscose fiber.

3. Fibrillation. When Lyocell fiber is in a wet state, small fibrils are pulled out of the fiber surface under mechanical force, which can change the properties of the fabric surface. Through enzyme treatment, longer fibrils are removed and secondary fibrillation is performed to obtain a peach skin effect.

4. Good dimensional stability. Lyocell fiber fabric has low shrinkage and good washability.

Technical indicators of Lenzing Lyocell:

Fineness: 0.9/1.3/1.7/6.7dtex

Quality length: 34/38mm Strength: 40-42cN/tex

Wet elongation 15-17% Wet strength 85% BISFA wet modulus 9-10 cN/tex

Lenzing Lyocell has developed the following product lines:

Lenzing Lyocell MICRO (Lenzing Lyocell microfiber), Lenzing Lyocell LF

Ser LF fiber), Lenzing Lyocell FILL (Lenzing Lyocell FILL fiber), etc.

The main purpose:

The development of Lyocell products roughly includes six product series: denim, suits, casual wear, yarn-dyed fabrics, shirts and underwear, and knitting.

Acrylic fiber and its uses

Part.9

Acrylic fiber – a modified acrylic fiber, which is a copolymer of acrylonitrile monomer and vinyl compounds containing flame retardant elements. It has a wool-like feel and high flame retardancy, and is acid and chemical resistant. . As a functional fiber, this fiber has been widely used in Japan, Europe and the United States for home textiles, protective clothing fabrics, decorative textile materials, etc.

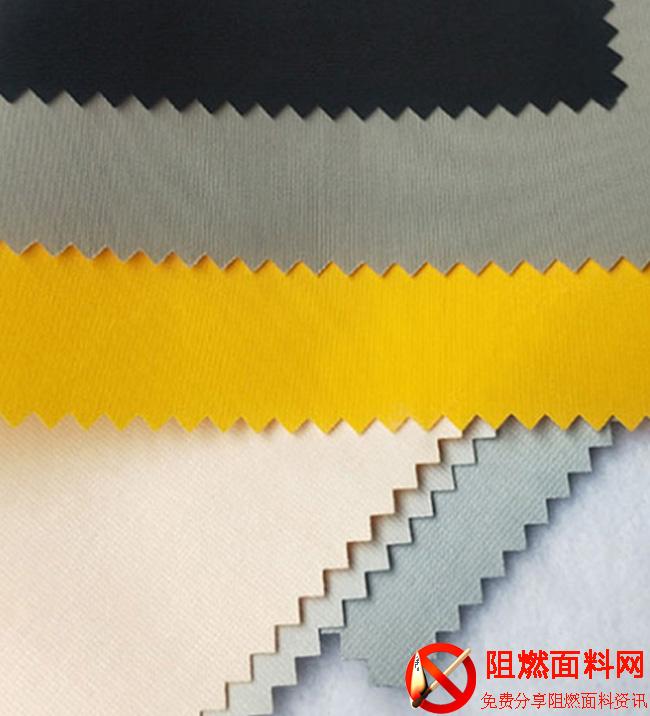

Fiber type: cotton, wool, high shrinkage

Fineness: 1.5DTEX-20DTEX

Length: 28-120mm

Oxygen limiting index: ordinary type 28-30

High flame retardancy: 30-3

Gloss: glossy, semi-matt, matt

Acrylic chlorine fiber product features:

Excellent flame retardant properties. ——The natural flame retardant properties of the fiber enable the material to pass the stringent flame retardant requirements of various countries. Even if it is blended with other natural fibers, it still has unchanged flame retardant properties.

Natural, soft feel. ——Acrylonitrile fiber has softness, natural feel, water absorption performance and comfort similar to other natural fibers.

There is no melting or shrinkage during combustion. ——There is no shrinkage or melting phenomenon when nitrile chlorine fiber clothing fabric is burned, but only carbonization, which effectively prevents skin burns caused by melt droplets.

The material has good chemical stability – resistant to acids, alkalis and other general organic and inorganic drugs, so it is used as filter cloth materials, special protective clothing materials and other industrial materials.

The material has good dyeing properties – bright color, good color fastness, sun resistance, no obvious degradation by sunlight, and can be used for parasols, etc.

Mainly used for: interior decoration, curtains, seat covers, and aviation blankets of various cars, trains, ships, airplanes, hotels, and conference rooms.

Polychloropropylene fiber and polychloropropylene fiber

Part.10

Polyvinyl chloride fiber is the product name I used for polyvinyl chloride fiber. The international product names are Rowell, Peceu (PCU), etc. It is one of the main varieties of chlorine-containing fiber.

The raw materials for manufacturing chlorine fiber are easy to obtain and the cost is low. Wet or dry spinning methods can be used.

Fiber specific gravity: about 1.4g/cm3

Fiber strength: approximately 2.64cN/dtex

Elongation at break: 12~28%

It has good elasticity, good flame resistance, wear resistance and weather resistance, and its aggregate has good warmth retention properties.

Main defects: Very sensitive to heat. In boiling water, the fiber can shrink significantly, the strength decreases, and the elongation increases to 150~280%, so the fabric cannot withstand ironing, has poor hygroscopicity, is difficult to dye, and is easy to produce static electricity.

Main uses: flame-proof sofa cloths, mattress cloths and other interior decoration products, chemical-resistant overalls, filter cloths, or processed into knitwear and warm cotton fillings, etc. In addition, the chlorine fiber can be used to produce a large amount of anions through friction, which has a certain therapeutic effect on the human body, and can be made into health care products.

The United States calls PVC fiber “Salon”, which mainly contains vinylidene chloride (more than 80%). PVC fiber has stable chemical properties and is difficult to dye. Its specific gravity is the heaviest among current textile fibers, at 1.7g/ cm3, the moisture regain is 0%, and the moisture absorption capacity is poor; the fiber breaking strength is 2.12cN/dtex, and the elongation is 15~25%; PVC has good flame retardancy and does not support combustion. Polypropylene fiber comes in two types: filament fiber and short fiber.