In 2021, global shipping demand is soaring, freight prices are rising, and congestion is serious. Containers used for shipping have also become in short supply. For a time, it was “hard to find a box”, almost recreating the “Luoyang paper price” in ancient times.

However, two years later, shipping demand reached a low point, freight rates fell back to pre-epidemic levels, and global shipping capacity and containers were severely oversupplied. In major ports around the world, empty containers are piling up.

Empty containers pile up at the port

“We rarely work overtime now. When we used to work overtime, we usually worked for 12 hours and had a 12-hour break. Now we work for 12 hours and have a 24-hour break.” A staff member who drives a container truck at the Shanghai Port revealed that now the port has There were a lot of empty containers and their workload was affected as a result.

Not only in Shanghai, the phenomenon of empty containers piling up is also happening in major ports across the country such as Guangzhou.

According to Caixin.com, some container shipping sources said that the current global container scale exceeds 50 million TEUs, and the container surplus ratio exceeds 10%.

The container availability index CAx also confirms this. According to data recently released by Container xChange, a global online container leasing and trading platform, Chinese ports were more crowded in January this year than in the past three years, indicating that China has more containers available.

“More containers are available” is not good news.

The container availability index CAx is released by Container xChange. It measures the ratio of incoming containers to outgoing containers at the port. An index higher than 0.5 indicates that there are more incoming containers than outgoing containers at the port, which can easily cause empty containers to accumulate at the port. An index lower than 0.5, indicates that there are more outbound containers than inbound containers, thus creating a situation of “it’s hard to find just one container”.

The report released by Container xChange also shows that compared with the past three years, the CAx index of Shanghai, Ningbo, Tianjin and other ports has remained high.

Specifically, in the first 10 weeks of this year, the CAx values of 40-foot containers in Shanghai were higher than the same period last year, reaching 0.66 in the second week and stabilizing at 0.64 in the following weeks. For comparison, in the third week of 2022, the CAx value of Shanghai’s 40-foot container was only 0.48, and the highest was only 0.59.

Container xChange data shows (above) that in the first 10 weeks of this year, the CAx values of 40-foot containers in Shanghai were higher than the same period last year.

Container xChange data shows (above) that in the first 10 weeks of this year, the CAx values of 20-foot containers in Shanghai were higher than the same period last year.

In fact, congestion has begun to ease significantly in 2022, freight rates have continued to decline, and container use has become routine. During the period when “a container is hard to find”, the container availability index of Shanghai Port has been lower than 0.1 for a long time. For example, from the end of November to the beginning of December 2021, the index was as low as 0.07.

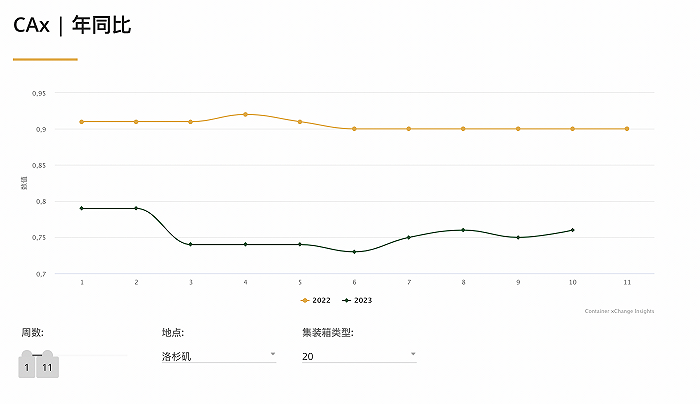

At the Port of Los Angeles in the United States, the accumulation of empty containers is even more severe. The CAx index shows that in the first 10 weeks of 2023, the CAx value of 40-foot containers in Los Angeles remained above 0.78, reaching a peak of 0.83.

In the first ten weeks of last year, this value was as high as 0.91. In addition, the Port of Antwerp in Northern Europe is also above 0.8, which means that the accumulation of empty containers in European and American consumer ports exceeds domestic levels.

Container xChange data shows (above) that in the first 10 weeks of this year, the CAx value of 20-foot containers in Los Angeles has declined compared with last year, but it is still at a high level of 0.73-0.79.

What is the reason for the excess accumulation of empty containers? When will foreign trade exports resume?

What are the causes of oversupply of containers and accumulation of empty containers? When will this situation be restored?

One of the reasons:

In the past two years, due to the frenetic shipping market conditions, a large number of containers have been produced around the world. According to Drewry’s latest container equipment report, container manufacturing companies have produced a large number of containers in the past two years. In 2021 alone, more than 7 million TEU containers were produced globally, which was nearly three times that of a regular year; last year, the number of global containers increased by another 2%. , the current global container volume reaches 50.9 million TEU.

As supply chain bottlenecks gradually return to normal, the number of excess containers in the global shipping market has reached 5 million TEU. These excess empty containers are piled up in terminals and warehouses around the world, with a surplus ratio of more than 10%.

Reason two:

In addition, weak global demand and sluggish foreign trade are important factors for the accumulation of empty containers at ports. Kuehne + Nagel Logistics sources said that the container shipping volume situation in the fourth quarter of 2022 is very pessimistic, and the export situation in January 2023 is comparable to February 2020, when the epidemic just broke out and work and production have not resumed.

A veteran freight forwarder in the industry said that generally the container shipping market will gradually recover 45 days after the Spring Festival.��The factors that have disturbed the market since the second half of 2022 still exist, and it will take at least 60 days in 2023, that is, until March 20 to observe the market recovery.

In addition, a freight forwarder surnamed Li pointed out that this was mainly because there was no wait for the outbreak of export orders before the year before. Many factories went on holiday in advance and the empty containers were not transferred out in time, resulting in a backlog at the port. After the year, it is already the off-season, and exports The quantity is not high, so empty boxes continue to accumulate. It is expected that foreign trade will not recover until May, and according to previous years, exports should rise after March.

The CEO of Hapag-Lloyd, the world’s fifth largest liner company, once said that despite the current sluggish demand and continued decline in container freight rates, orders for goods and transportation services will pick up again as demand for restocking increases. He expects a pick-up to occur in March or June.

Reason three:

In addition, an employee of a shipping company pointed out that the current rapid increase in exports from Southeast Asia to Europe and the United States is also one of the factors leading to the decrease in domestic exports and the increase in empty containers.

The excess of containers will bring about a series of subsequent impacts. Container xChange analyzed in its “23 Shipping Industry Trends in 2023” that as there is a glut of containers in the market, shipping companies will either continue to reduce ship capacity or continue to sail with empty ships.

For example, Maersk has been adjusting its shipping capacity from Asia to other continents. Under this circumstance, it is expected that the shipping industry will usher in a price war in 2023.

</p