As the concept of green environmental protection slowly takes root in people’s hearts, there is increasing attention to the PTFE hollow fiber membrane manufacturer. At the same time, the manufacturer produces and develops A series of filtration products are also constantly in demand and used by people.

The membrane separation process is a dynamic filtration process. Macromolecule solutes are blocked by the membrane wall and flow out of the membrane module with the concentrated solution. The membrane is not easily blocked. Can be used continuously for a long time. The filtration process can operate at normal temperature and low pressure, without phase changes, and is highly efficient and energy-saving.

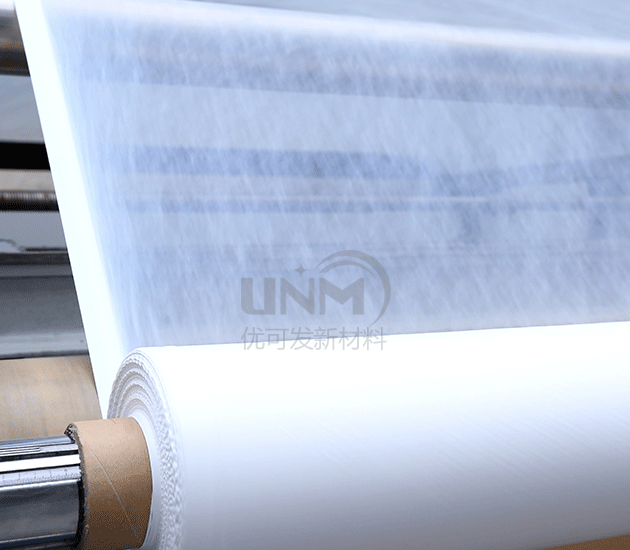

The pore-forming mechanism ofPTFE hollow fiber membrane: under the action of extrusion, shearing, stretching, etc., PTFE resin particles Entanglement, and initial fibrillation; further stretching can cause the microfibers in it to elongate, and then form a “fibril-node” microporous structure. Therefore, during product processing, extrusion, shearing, stretching and other effects are very important to the formation of microporous structure. During the continuous normal operation of the hollow fiber ultrafiltration membrane, various cleaning methods need to be carried out regularly. At present, the commonly used cleaning methods mainly include the following: back pressure backwashing method, isobaric hydraulic washing method, and chemical cleaning method.

It is a high-tech enterprise focusing on the research and development, production and sales of PTFE hollow fiber membrane, with an area of nearly 8,000 square meters. Factory area, professional production equipment, strong scale, and we are a partner of Fortune 500 companies; the products we produce are all produced with imported raw materials, and we have a full set of advanced production equipment and testing instruments, and complete pre-sales, sales, and after-sales services system. If you are interested, please enter the store for consultation.

</p