Overview of cotton processing Cotton processing process

(1) Sawtooth ginning process

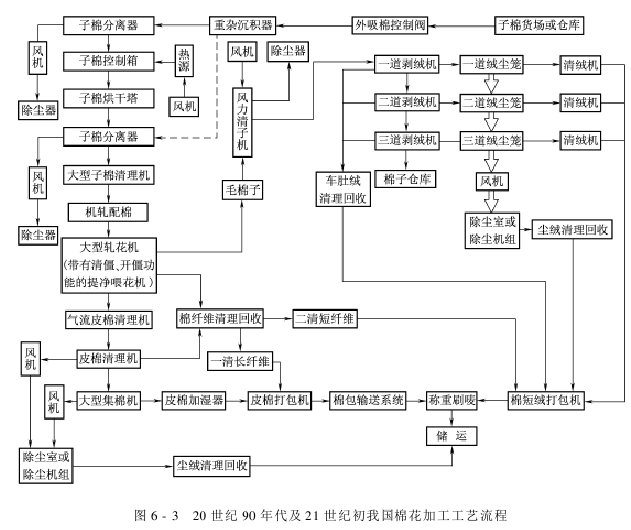

The cotton finishing process flow in my country in the 1980s is shown in Figure 6-2. The cotton finishing process flow in my country in the 1990s and early 21st century is shown in Figure 6-3.

Based on 2004 The “Technical Regulations for Cotton Finishing of Cotton Quality Inspection System Reform Pilot Enterprises” published in 2017 requires that the cotton finishing process is as follows:

Goods yard cotton → Cotton heavy debris cleaning machine → Cotton unloader → Cotton automatic control feeding Machine → cotton dryer → cotton cleaning machine → cotton matching device → gin → (lint cleaning machine) → cotton collector → (humidification) → baler → cotton sample → cotton bale measurement → cotton bale information management System → Print barcode → Integration of automatic cotton bale conveying system and finishing equipment is the trend of cotton finishing progress. The following introduces the process flow of some complete sets of ginning and finishing equipment.

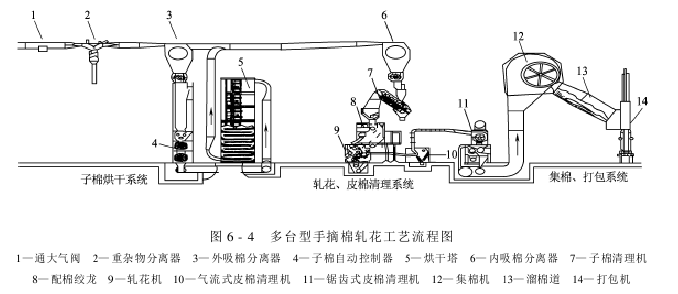

1. Hand-picked fine-staple cotton finishing process

Figure 6-4 shows the multi-station hand-picked cotton ginning process.

Goods yard or The cotton in the warehouse is transported to the production workshop by pneumatic conveying. A vent valve is also installed on the conveying pipeline before the heavy debris depositor is installed to realize automatic control of external suction cotton. When the moisture content of the cotton is high and is not suitable for the requirements of the ginning process, the cotton enters the hot air duct of the drying system through the external suction cotton separator and the automatic control box of the cotton, and is blown to the dryer for drying by the hot air. , and then unloaded into the high-efficiency blower for cleaning by the internal suction cotton separator; when the moisture content of the sub-cotton is appropriate, the sub-cotton can be adjusted to directly enter the internal suction cotton separator, and then unloaded into the high-efficiency blower from the internal suction cotton separator. Clean up. The dusty air after separation from the cotton is introduced into the dust removal equipment for purification treatment through the return air duct, and then discharged into the atmosphere. After the cotton is cleaned and loosened, it is delivered to the large sawtooth gin using a positive pressure cotton distribution device or a spiral cotton distribution device. After being sorted by a sawtooth gin, the fibers and cotton seeds are separated. Whether the lint should be cleaned can be determined based on the quality of the lint. When the quality of the lint meets the requirements, the four-way valve of the lint cleaning machine (referred to as the lint cleaning machine) can be adjusted so that the lint is sent directly to the common lint collecting device without going through the lint cleaning machine. Packing machine into bales. Under normal circumstances, lint should be sent to a lint cleaning machine for cleaning. The automatic control of the amount of cotton is realized through the interlocking between the equipment motors and the interlocking of the micro switches set on the cotton storage box (or cotton distribution box). When the sub-cotton in the positive pressure distribution box reaches a certain height, the micro switch on the upper part is triggered, thereby controlling the feeding motor on the internal cotton storage box at the lower part of the high-efficiency cleaning machine to stop working, and at the same time, the sub-cotton is automatically controlled. The DC feeding motor on the box also stops feeding. When the cotton in the automatic control box reaches a certain height, the micro switch on the upper part is triggered, allowing the air valve to communicate with the air to stop external suction of cotton. When the drying process is not used, the feeding motor on the internal cotton storage box is directly connected to the air venting valve to control the air venting valve to communicate with the air to stop external suction of cotton. The infertile particles and impurities discharged from the sawtooth gin and leather cleaning machine are sent to the recycling workshop using pneumatic conveying devices; the long-fiber cotton is sent to the stripping workshop using a spiral conveying device for sorting.

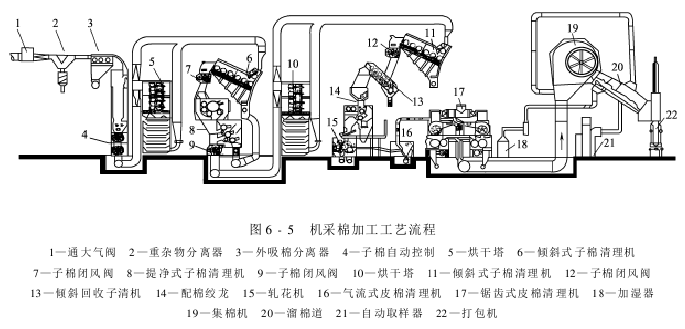

2. Machine-picked cotton finishing process

Since the foreign impurities in machine-picked cotton are several times higher than those in hand-picked cotton, and the moisture content of the cotton is higher, the cotton needs to be processed multiple times before ginning. Cleaning and drying 1 to 2 times, the ginned lint needs to be cleaned 2 or more times.

Figure 6 -5 shows the process flow of machine-picked cotton finishing. Compared with the cotton finishing process of hand-picked cotton, this process increases the number of drying times of sub-cotton and the number of times of cleaning of sub-cotton (after drying the sub-cotton, an extraction machine is added to remove impurities such as cotton bolls, boll shells, and cotton branches). Clean type lint cleaning machine, and after the second lint drying, a tilting lint cleaning machine with lint separation function is used) and the number of lint cleaning (using one airflow lint cleaning and two sawtooth cleaning) Roller lint cleaning), added lint humidification.

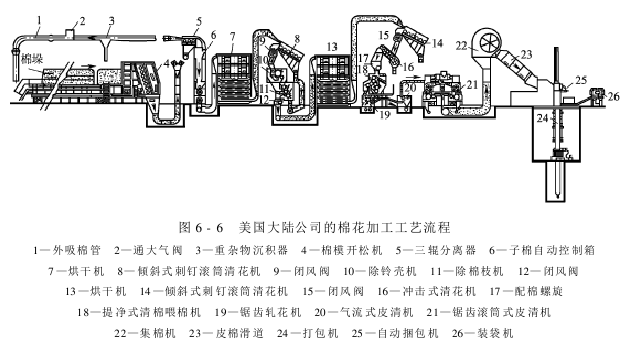

3. The cotton finishing process in the United States

The gin factories that finish upland cotton in the United States have a large scale of production. They generally have 2 to 5 large sawtooth gins. On average, each factory produces more than 20,000 tons of lint per year. The ginning mill has strong economic and scientific research strength, and often adopts advanced technology and updates equipment.

But the ginnery only sorts out commercial cotton, and it is a single ginning production. The stripping of cottonseed is done in the oil mill. Seed cotton is sorted by a special cotton seed finishing factory. In addition to the “foam acid delinting” process, the ginning cotton also undergoes various extraordinary treatments.

Agricultural production in the United States has been highly mechanized and modernized. All cotton sorted in the ginnery is picked mechanically, of which 80% is picked in batches by horizontal spindle cotton pickers (with an impurity content of 4% to 10%), and 20% is picked in one go by roller pickers ( Impurity content 30% ~ 40%). Therefore, there are two types of cotton finishing processes in the United States. The cotton finishing process of divided picking mainly includes: drying of cotton, sub-cotton cleaning, ginning, lint cleaning, cotton collection and packaging and other processes. The one-time picking cotton finishing process includes: first using a bell shell remover and a cotton branch remover to remove a large number of bell shells and broken branches, and then finishing according to the divided picking cotton finishing process.

Seed cotton collected in the field is either pressed into a cotton mold (length × width × height: 7315mm × 3048mm × 2438mm, weighing about 8000kg) by a cotton molding machine, and is temporarily stored in the open air. Cotton molds are sent to the ginnery by an automatic loader, or transported to the ginnery by a high-top trailer. The cotton mold is transported to the cotton feeding workshop of the ginnery and is unloaded on the conveyor belt. While being transported, the cotton mold opening machine grabs the cotton balls and sends them to the feeding port of the outer suction pipe. After the high-top trailer transports the cotton to the cotton feeding workshop of the ginnery, an external suction tube with a universal ball head that can rotate and lift is used to suck cotton directly from the trailer.

Continental America’s cotton production process is as follows.

(1) Ginning process:

Cotton mold feeding (or absorbing) → heavy duty separator → cotton mold opening machine → three-roller separator → cotton control box → drying tower → oblique six Roller blowroom (separately) → Cleaning and cleaning machine → Drying tower → Inclined six-roller blowroom (separating) → Auger with cotton (with overflow box) → Cleaning flower feeding and gin → Sawtooth leather cleaning machine (cleaning 2 (pass) → cotton collecting machine → top pressure packaging → sampling → weighing → packaging → warehousing. Figure 6-6 shows the cotton finishing process of the American Continental Company.

(2 ) Infertile recycling process:

Collecting infertile dust cage and cleaning infertile machine Horizontal infertile baling machine

(3) Dust removal process: Using Shakron first-level dust removal, impurities and dust are removed by twisting After the dragons are concentrated, the wind blows a dragon into the far distance of the workshop, and then is unloaded and stacked in the open air.

(4) Cotton seed recycling process: Cotton seeds are transported by wind to an elevated storage bin. There is a discharge port at the bottom of the storage bin, and the cotton seeds can be unloaded into a trailer box and transported away.

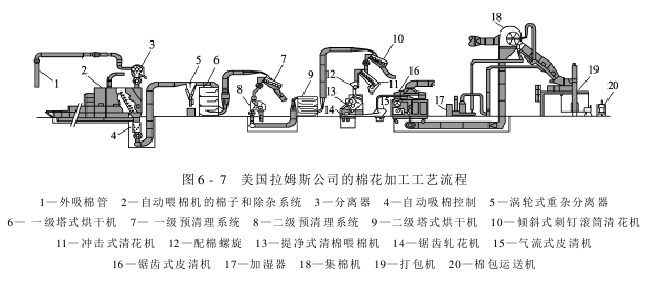

Figure 6-7 shows the cotton finishing process flow of American Rams Company.

(two ) Top roller gin process

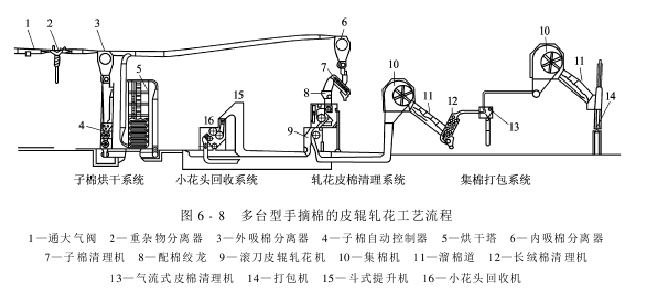

Top roller gin machine is mainly used for finishing long-staple cotton. Figure 6-8 shows the top roller ginning process of multiple hand-picked cotton provided by Shandong Swan Cotton Machinery Co., Ltd.

AAAVEGTRHYTJ