Flame retardant fabrics woven and finished with 100% natural fiber “cotton” are here~~

Flame-retardant fabrics are flame-retardant treatments based on dyed fabrics, or flame retardants with flame-retardant functions are added to the fibers through technologies such as polymer polymerization, blending, copolymerization, composite spinning, and extrusion modification. , making the fiber flame retardant. The finished product can not only effectively prevent the spread of flames, but also protect the original properties of the fabric. It can automatically extinguish or effectively slow down the spread of flames, carbonize the fabric to form an isolation layer, and at the same time has the characteristics of not melting, dripping, or burning when exposed to fire. , has good flame retardant effect. (Flame-retardant fabrics are not inflammable. Even if they are ignited by an open flame, they will automatically extinguish within 12 seconds after leaving the open flame)

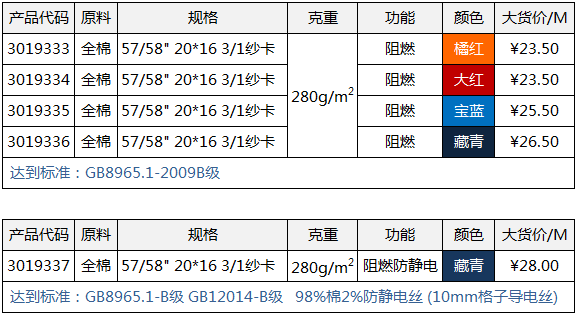

The cotton flame-retardant fabric recommended below is woven and finished from 100% natural fiber “cotton”. It has the characteristics of breathable and moisture-permeable, moisture-absorbing and quick-drying, soft touch, and soft luster. It also retains the anti-static properties of cotton fiber. Ecological and environmentally friendly features. Protective clothing made of this fabric is comfortable to wear, breathable and moisture-permeable, and non-irritating to the skin. It is the first choice for customers who value natural and environmentally friendly properties. This product meets the requirements of OEKO-TEX STANDARD 100, and its flame retardant properties can reach GB8965-2009, EN11611, EN11612, NFPA2112 and other standards.

Classification of flame retardant fabrics

Flame-retardant fabrics can be divided into: according to washability standards:

1. Permanent flame retardant fabric (woven with flame retardant fiber, the flame retardant effect will not change no matter how many times it is put into the water)

2. Washing resistance (more than 50 times) flame retardant fabric

3. Semi-washable flame retardant fabric

4. Disposable flame retardant fabrics (decoration, curtains, cushions, etc.)

The production process of flame-retardant cloth and the introduction method of additives can be divided into: flame-retardant treatment of fibers and flame-retardant finishing of fabrics

Flame retardant treatment of fibers:

1. The flame retardant mechanism refers to adding a certain flame retardant to some inherently flammable raw fibers (such as polyester, cotton, and acrylic) to inhibit free radicals during the combustion process; or to change the thermal decomposition process of the fiber to promote Dehydration and carbonization; in some cases, the flame retardant decomposes and releases non-flammable gas to cover the surface of the fiber and isolate the air.

2. Flame retardant treatment method

1) Improve the thermal stability of fiber-forming polymers

2) Flame retardant modification of raw silk

Flame retardant finishing of fabrics:

1. Flame retardant mechanism

1) Covering layer theory: Flame retardants can form a glass-like or stable foam covering layer at high temperatures, which can insulate heat, oxygen, prevent flammable gases from escaping outward, and play a flame retardant role.

2) Non-combustible gas theory: The flame retardant decomposes into non-combustible gas when heated, and the concentration of combustible gas decomposed from cellulose is diluted to below the lower combustion limit.

3) Endothermic theory: Flame retardants undergo endothermic reactions at high temperatures, lowering the temperature to prevent the spread of combustion. In addition, the heat can be transferred out quickly after fabric finishing, so that the cellulose cannot reach the temperature of ignition and combustion.

4) Chemical reaction theory (catalytic dehydration theory): The flame retardant reacts with the fiber as a Lewis acid at high temperatures, causing the fiber to catalytically dehydrate and carbonize, reducing the generation of flammable gases.

2. Flame retardant finishing method

1) Padding and baking method: the most widely used flame retardant finishing process. The process flow is padding-prebaking-baking-post-processing. Padding fluid is generally composed of flame retardants, catalysts, resins, wetting agents and softeners, and is configured into an aqueous solution or emulsion for finishing.

2) Dip and bake method (absorption method): The tissue is immersed in the flame retardant liquid for a certain period of time, and then dried and baked to make the flame retardant liquid absorbed by the fiber polymer.

3) Organic solvent method: It uses non-water-soluble flame retardant. Its advantage is low energy consumption during flame retardant finishing. However, in actual operation, attention should be paid to the toxicity and flammability of solvents.

4) Coating method: Mix the flame retardant into the resin, and the flame retardant is fixed on the fabric through the adhesion of the resin. According to different mechanical equipment, it is divided into blade coating method and pouring coating method.

Finishing process and commonly used additives for flame retardant fabrics

At present, the mainstream flame retardant processes include promethazine fumigation process and CP finishing process. The Prubenzin process allows appropriate formaldehyde for clothing that is not worn next to the body. The advantage is that the loss of breaking strength of the fabric is small. The relative fastness of fabrics made from the same gray fabric after finishing is much higher. Basically, Prubenzin is It can meet the requirements of GB8965.1-2009 Level B standard, while CP can only meet the Level C standard of this standard, and it is basically difficult to achieve Level B standard. However, for flame-retardant clothing that is close to the skin, it is not recommended to use fabrics with proben-finished technology. Instead, it is recommended to use CP technology with low formaldehyde content or permanent flame-retardant fabrics such as acrylonitrile and aramid. For customers with higher requirements on color and feel, it is also recommended to use flame-retardant fabrics made of CP process or acrylonitrile and aramid. At present, most customers still use flame-retardant fabrics made of flame-retardant fabrics finished with polybenzene process on their jackets. Work clothes.

Process flow:

Proben: padding flame retardant finishing liquid → pre-drying → ammonia fumigation → washing → drying → pre-shrinking → finished product (requires hot air priming machine and ammonia fumigation machine)

CP: padding flame retardant finishing liquid → pre-baking → baking → washing → drying → pre-shrinking → finished product (general dyeing factories can do this)

Commonly used additives:

According to the application method, they are divided into additive flame retardants and reactive flame retardants. According to the composition, additive flame retardants mainly include inorganic flame retardants, halogen flame retardants (organic chlorides and organic bromides), phosphorus flame retardants Flame retardants (red phosphorus, phosphate esters and halogenated phosphate esters, etc.) and nitrogen-based flame retardants, etc.