New European and American regulations have made Jinan flame retardant fabric popular

“Last year’s orders have been completed, but this year’s orders have not been received.” This is a sentence that reporters often hear when interviewing export companies recently. Affected by factors such as the continued escalation of the European debt crisis and the sluggish global economic recovery, in the first half of this year, overseas market demand decreased, prices were depressed, and the raw materials and labor costs required for corporate production increased. Export companies had a very difficult time, and some companies even went bankrupt.

How do export companies cope with the “order shortage”? On the 20th, through the coordination of the Municipal Council for the Promotion of International Trade, our reporter visited three export companies whose exports grew against the market and listened to their stories behind the orders.

export product

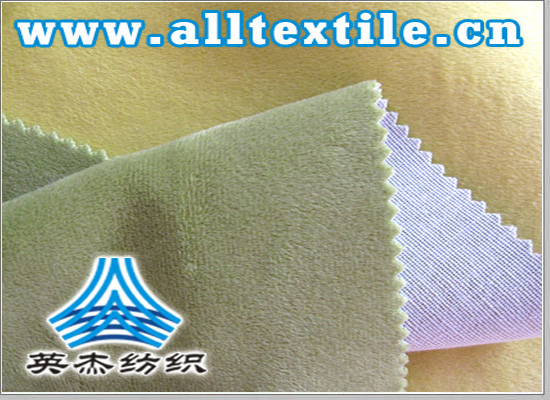

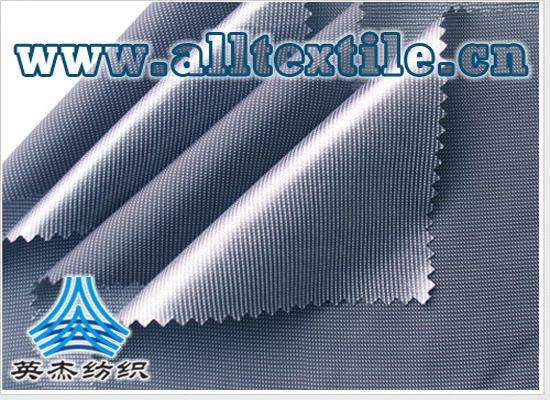

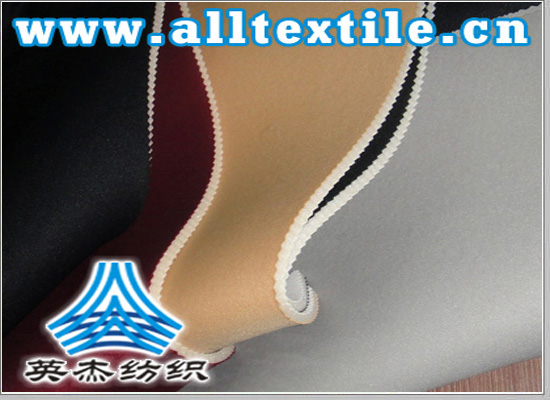

Flame retardant cloth

Being the only one in Asia, you never have to worry about orders

“I just came back from participating in an exhibition in the United States a few days ago and heard good news. The United States may introduce new regulations requiring that by the end of this year, pajamas and underwear must be made of flame-retardant materials.” On the 20th, Jinan Lu’s Weaving and Dyeing Co., Ltd. Lu Changjiang, general manager of the Clothing Co., Ltd., couldn’t wait to tell the news as soon as he saw the reporter. In Lu Changjiang’s eyes, the industry regulations that are about to be launched in this country thousands of miles away are business opportunities and a steady stream of orders.

The factory is currently the only company in Asia that produces environmentally friendly extra-wide permanently fully flame-retardant fabrics. With this unique advantage, his factory not only survived amidst the collapse of textile printing and dyeing export companies, but also managed to survive in this ” We have made “Sunrise Products” in the “Sunset Industry” and have never had to worry about orders in the past 15 years.

Europe and the United States are enacting laws one after another, and fabrics that are not afraid of fire are becoming popular.

On the morning of the 20th, the reporter drove to Lushi Weaving, Dyeing and Garment Co., Ltd. located in Zhangqiu City. The factory door is not big and not very conspicuous, and there are only a few rows of board houses in the factory area. The factory’s reception room doubles as a product showroom and is located in the first row of board rooms upon entering. The shelves in the reception room are filled with bed sheets, pajamas, curtains, etc. of various colors. At first glance, these things are no different from what we usually see.

In order to show reporters the uniqueness of these fabrics, Lu Changjiang deliberately picked up a piece of cloth, pointed it at the cloth with a lighter and started to light it.

A magical scene appeared. The reporter saw that no matter how raging the flames of the lighter were, it would only leave a black spot the size of a fingernail on the edge of the fabric. It would die out after a burst of white smoke and would not continue to spread along the fabric. It will not burn like ordinary fabrics when exposed to fire. “This is the function of flame-retardant cloth.” Lu Changjiang explained that this kind of flame-retardant cloth adds chemical agents through chemical processing on the basis of ordinary cloth, which can achieve fire prevention effect.

After the “9·11” incident in the United States, European and American countries further realized the importance of fire prevention. The United States took the lead in legislation requiring that curtains and bedding used in hotels, restaurants and other public places must use flame-retardant materials. Immediately afterwards, European countries such as the United Kingdom and Germany also introduced similar regulations. Moreover, European countries have put forward higher requirements for the environmental protection attributes of such products.

The reporter learned that there are currently several companies in China that can produce such cotton flame-retardant fabrics, but this is the only one whose products have entered the “International Environmentally Friendly Textile Association’s Active Chemical Products Catalog” and can meet European standards. “China is also paying more attention to fire protection. Next, our products will also be marketable in the domestic market. This is a sunrise industry.” Lu Changjiang told reporters with confidence.

Supplied to a British merchant for 15 years

The relationship between flame retardant fabrics was at an overseas exhibition in 1997. At that time, Lu’s Weaving, Dyeing and Garment Co., Ltd. was small in scale and had weak production capacity. When it participated in the Frankfurt Home Textile Exhibition in Germany with the Jinan Council for the Promotion of International Trade, it made friends with a British businessman. This British businessman specializes in supplying military textiles to NATO troops. It has high requirements for the fire-retardant properties of the fabrics and hopes to find a partner in China. But at that time, there were very few companies doing this kind of business in the Chinese market. Lu Changjiang was keenly aware that this was a gap in the market, and with the professional skills accumulated over the years, heolor:#444444;font-family:””>

Wearing the same gold-rimmed glasses and the same smart short-cut hair, the reporter was really surprised to see Han Xiling, general manager of Huachen Industrial Co., Ltd., and her old partner, Mr. Feng of High-tech Huaneng Hydraulic Machinery. Because a staff member of the Jinan Council for the Promotion of International Trade who was traveling with us previously told reporters that this is a foreign trade company that mainly exports hydraulic machinery. In such a rigid industry, its top managers are all female.

But in the following interview, the reporter got a glimpse of some of the secrets.

In a few days, Jinan City Council for the Promotion of International Trade will organize a group of companies to participate in an exhibition in Thailand, and Huachen Industrial is among the companies accompanying them. During the interview, Han Xiling did not forget her work and took the opportunity to discuss her itinerary during the exhibition with the staff of the Council for the Promotion of International Trade. When she learned that she would only have two days in Thailand, she began to worry that the schedule was too tight: “This time I go to Thailand, I have more than ten clients to visit. The group tour is too slow and I can’t wait. I will do it alone when I get to Thailand.” This kind of work rhythm is the normal state of Han Xiling and others. “There are really not many people like us who are over 60 years old and still working hard in the company. Mr. Feng is also over 60 years old and is in charge of production. He falls asleep in the middle of the night and is often woken up by phone calls from the factory.” Han Xiling said.

Speaking of sales in the past half year, Han Xiling said “not bad”. She told reporters that despite the sluggish international economic situation, the company’s sales in the first half of the year were 30% higher than last year. “This is the result of our continuous development of the international market.” Han Xiling said frankly that although mechanical hydraulics is a relatively high-tech industry among domestic foreign trade export companies, there is still a big gap in accuracy compared with similar industries in Germany. “Customers come to buy Chinese products because of the low prices. Although we have many orders now, the prices are kept very low.” Han Xiling said that the reason why she is visiting customers so hard now is to accumulate more Customer resources, first open up as many markets as possible through low-price strategies, and then cultivate long-term customers.