“Honeycomb” on the aircraft – aramid paper honeycomb sandwich structure composite material

“Honeycomb” on the aircraft – aramid paper honeycomb sandwich structureComposite material

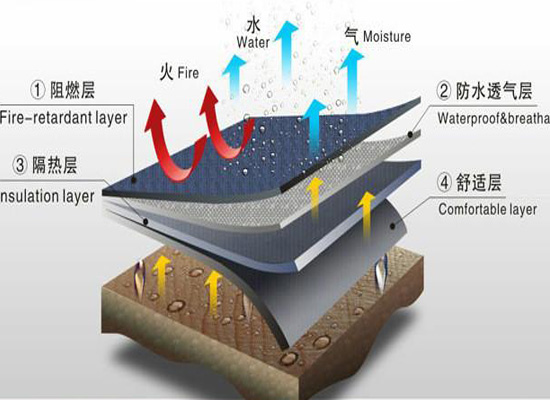

Reducing weight is an important pursuit in aircraft design and manufacturing. It can give military aircraft stronger flight performance and improve the fuel economy of civil aircraft. However, if the thickness of the plate-like parts on the aircraft is too thin, it will face problems of insufficient strength and stiffness. Compared to adding a support frame, adding lightweight, rigid sandwich material between two panels can significantly increase load-bearing capacity without significantly increasing weight.

This is like the structure of the wind turbine blades that I once shared:

A layer of balsa wood or foam core is filled between the inner and outer surfaces of the skin made of fiberglass reinforced epoxy resin (GRP). Balsa wood was also the earliest sandwich material used in aircraft. For example, the famous wooden aircraft during World War II, the British Mosquito bomber, was made of two layers of birch and one layer of balsa plywood.

In the modern aviation industry, core materials used include honeycomb structures and foam plastics. The seemingly weak honeycomb can withstand the crushing of heavy trucks because the stable honeycomb grid structure hinders buckling and deformation. This is the same principle as the cardboard boxes made of corrugated paper that have strong compression resistance.

Aluminum is the most commonly used metal on aircraft, so it is logical to use the structure of aluminum alloy panels + aluminum honeycomb sandwich cores.

This is a section of the wing of a VFW614 aircraft. The trailing edge and spoiler of the wing are shaped directly from the aluminum honeycomb structure.

By the way, this VFW614 is a strange thing with an engine mounted on the wing. It was developed by West Germany’s United Aviation Technology-Fokker (VFW-FOKKER) Aircraft Company. It is a short-range passenger aircraft that can carry 40 passengers. First flown in 1971, it was West Germany’s first development of a commercial jet airliner after World War II (East Germany’s attempt was the Bader 152, which first flew in 1958). The aircraft was not a commercial success and only 13 were built, but it was still a milestone in the German aviation industry. The more famous story that followed was the rivalry between the Franco-German cooperation Airbus and the American Boeing Company.

When composite materials are increasingly used in aircraft manufacturing, can aluminum honeycomb be replaced?

The answer is yes. The most commonly used aramid paper honeycomb composite material on modern aircraft is honeycomb-covered panels made of composite materials such as carbon fiber reinforced resin and used for aircraft floors, doors, interior parts, tail fins, rudder surfaces, fairings, etc. Paddles, etc. are also used in the inner walls, ceilings, luggage racks, etc. of high-speed trains.

As the name suggests, this honeycomb is made of a special kind of paper – aramid fiber paper.

First, apply adhesive strips on the aramid paper. The strip width is equal to the side length of the honeycomb hole (for a hexagonal honeycomb), and the strip spacing is 4 times the side length. The adhesive strip is applied by the gravure printing method. There are grooves with specific width and spacing on the adhesive roller, and the adhesive strip is transferred to the aramid paper. Two adjacent layers of aramid paper are stacked in dislocation, and the adhesive strip is solidified by hot pressing. Next, like playing an accordion, the aramid paper stacks are stretched into honeycombs. It also needs to be baked to release the rebound stress and shape the honeycomb.

Through impregnation treatment (usually impregnated with phenolic resin), the pores between aramid fibers are filled and solidified to obtain the finished honeycomb. Resin plays a role in bonding fibers and transmitting loads. Through cutting processing, honeycombs can be made into various shapes.

The above-mentioned honeycomb manufacturing process comes from AVIC Composite Materials Co., Ltd., a subsidiary of the Aviation Industry Corporation of China. It can currently produce honeycomb cells with a cell side length of 1.8-5.5 mm, a density range of 29-144 kg/m3, and a maximum size of 3900×1850×900 mm. Paper honeycomb.

However, the key raw materials for the production of aramid paper honeycombs – aramid fiber and aramid paper, used to be a “stuck neck” problem that we have faced for a long time.

Commonly referred to as aramid, generally refers to para-aramid and meta-aramid. Para-aramid is made from the condensation polymerization of terephthaloyl chloride and para-phenylenediamine. It is also called “aramid 1414” based on the position of the substituent on the benzene ring. Of course, its most famous trade name is DuPont of the United States. The company’s “Kevlar”. Meta-aramid is formed by the condensation polymerization of isophthaloyl chloride and meta-phenylenediamine, also known as “aramid 1313”. DuPont’s trade name is “Nomex”.

In comparison, para-aramid has higher strength and modulus, and the aramid paper and honeycomb produced have better mechanical properties, while meta-aramid has better heat resistance and flame retardant properties. The aramid filaments with a diameter of about 10 microns obtained by spinning are cut to obtain chopped fibers, one of the important raw materials of aramid paper, with a length of 5 to 6 mm. Chopped fibers have high strength, but have smooth surfaces, fewer active groups, and lack of interweaving force between fibers. They cannot make paper alone, but serve as “rebar” and are combined with “concrete” – aramid pulp or fibrid fibers. , becoming a paper with high strength. Pulp is obtained by beating chopped fibers. The original fiber structure is partially broken up, and the surface is plush, exposing more amino groups, which can form more hydrogen bonds, thereby bonding the chopped fibers together; Shen Fibers are short, fluffy fibers that precipitate out of a polymer solution under vigorous stirring.

Aramid fibers dispersed in water are made into paper (pictured in a laboratory test), similar to the traditional papermaking process. But aramid paper requires an extra step of hot pressing to bond the aramid fibers. Meta-aramid has a lower softening temperature and the fibers are easier to combine into paper, so it is more widely used in aramid-paper honeycomb composites. In addition, aramid paper is also used as insulating paper in the electric power and motor industries. The industrial production of aramid fiber began in foreign countries in 1967, while my country’s aramid fiber industry started in the 1980s. There was a large gap with foreign countries. Facing the technological blockade of foreign enterprises, aramid fiber and aramid paper have long relied on imports. Yantai Minshida (a subsidiary of Taihe New Materials, which produces spandex and aramid) has cooperated with Zhang Meiyun, a professor of pulp and paper engineering at Shaanxi University of Science and Technology, to break the foreign monopoly and realize the localization of aramid paper. Currently, there is Chaomeisi in China New Materials, Shenzhen Haotian Longbang Composite Materials Co., Ltd., etc. are able to mass-produce aramid paper.