Process practice and discussion of aramid blended yarn

Aramid blended yarn process practice and discussion

1. Characteristics and uses of fiber

1.1 Characteristics of aramid fiber

1.1.1 Good mechanical properties

Aramid is a flexible polymer material. Its low stiffness and high elongation characteristics make it the same spinnability as ordinary fibers. It can be processed into various fabrics or non-woven fabrics with conventional spinning machines. Moreover, aramid fabrics are wear-resistant and tear-resistant. , can be widely used in special fields such as labor protection and military product production.

1.1.2 Excellent flame retardant and heat resistance

Aramid fiber is a kind of flame-retardant fiber. Its limiting oxygen index LOI value is ≥28%. It is a flame-retardant fiber. Therefore, aramid fabric will not burn, melt or produce droplets in the air, does not emit harmful gases, and does not support combustion. , self-extinguishing.

1.1.3 Stable chemical properties

Aramid fiber can be used for a long time at high temperatures of 220°C without aging. Its electrical and mechanical properties can remain effective for 10 years, and its dimensional stability is excellent.

1.1.4 Radiation resistance

Aramid fiber has excellent radiation resistance to α, β rays and ultraviolet rays. For example, when the amount of beta-ray radiation accumulates to 1000 Mrad, its intensity remains basically unchanged.

1.1.5 Uses of aramid fiber

Aramid fiber can be used in various aspects of the national economy such as aerospace, electromechanical, construction, automobiles, and sporting goods. It is mainly used for labor protection (firefighting suits, firefighting boots, firefighting bags, etc.), special equipment combat suits (flight suits, firefighting suits, etc.) It is a new type of high-tech synthetic fiber that has the characteristics of ultra-high strength, high modulus, high temperature resistance, acid and alkali resistance, and light weight. The morphological structure of aramid fiber is shown in Figure 1.

Figure 1 Morphological structure of aramid fiber

1.2 Properties of flame retardant viscose fiber

1.2.1 Permanent flame retardant performance

There is almost no flame when flame-retardant viscose fiber burns, and it goes out in a very short time. It will neither continue to burn nor smolder.

1.2.2 Excellent thermal insulation performance

Flame-retardant viscose fiber can effectively prevent high-temperature heat radiation transmission. The fiber does not shrink or deform under high temperatures.

1.2.3 Arc resistance and antistatic properties

Flame-retardant viscose fiber maintains the original natural antistatic properties of viscose fiber.

1.2.4 Hygroscopicity

Clothing made from flame-retardant viscose is comfortable and breathable. Facilitates sweat discharge in high temperature environments.

1.2.5 Excellent dyeability

Flame-retardant viscose fiber has the characteristics of natural fibers that are easy to color, brightly dyed, and have good color fastness.

1.2.6 Green environmental protection

Flame-retardant viscose fiber is made from regenerated natural plants. The waste can be naturally degraded and meets environmental protection requirements. Phosphorus-based flame retardants also meet EU flame retardant and halogen-free requirements.

1.2.7 Uses of flame retardant viscose fiber

Flame-retardant viscose fiber is a new high-tech fiber material with flame-retardant and anti-melting properties. Compared with synthetic polyester flame-retardant fiber, it not only ensures the excellent physical properties of the fiber, but also achieves the characteristics of low smoke, non-toxic, no odor, no melting and dripping, etc. With the advancement of mandatory flame-retardant regulations at home and abroad and the improvement of people’s fire safety awareness, the application scope of flame-retardant textiles is expanding day by day, extending to home furnishings, underwear and other fields. The requirements for flame-retardant textiles have also expanded from simple protection to the pursuit of more Best comfort, breathability and performance. The morphological structure of flame-retardant viscose fiber is shown in Figure 2.

Figure 2 Morphological structure of flame retardant viscose fiber

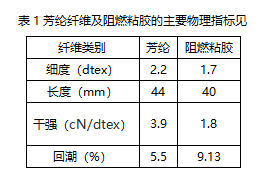

1.3 Main physical indicators of aramid fiber and flame retardant viscose

The main physical indicators of aramid fiber and flame-retardant viscose are shown in Table 1.

2. Technical requirements of spinning process

2.1 Preparation of color materials

The customer requires colored spinning, so aramid needs to be dyed, using carrier dyeing. The dyeing process is similar to that of polyester. The principles for selecting carriers are: good dyeing effect, less dosage, and non-toxic and odorless. After pretreatment, the aramid fiber is added to the carrier HPS-505 at 50 degrees, run for 10 minutes, raise the temperature to 70 degrees, add cationic dye, run for 10 minutes, add sodium nitrate (sodium chloride), run for 10 minutes, and then run at 1 degree/minute Raise the temperature to 130 degrees and keep it warm for 60 minutes, cool down to 75 degrees at 1 degree/minute, color, drain, and clean (see Figure 3 for the aramid dyeing process). Flame retardant viscose is blended with raw white fiber and dyed aramid.

Aramid dyeing process

2.2 Handling of raw materials

Since the specific resistance of aramid fiber after dyeing is high and the electrostatic phenomenon is serious, improper pretreatment of the fiber can easily lead to cylinder twisting, drawing, slitting, roller wrapping, etc. Therefore, the raw materials need to be cured and a certain amount of antistatic agent and antistatic agent added. water, and strictly implement the curing time (must ensure more than 16 hours, and place it in an environment of 28 degrees and relative humidity of 65%).

Flame-retardant viscose is a white masterbatch cellulose fiber. In order to avoid the formation of white knots during carding, the fiber cannot be cured with oil or water. After curing, aramid is blended with flame-retardant viscose.

2.3 Process flow

Because aramid and viscose fibers have large static electricity, are fluffy, and have good fiber length consistency, in order to reduce fiber damage during spinning, a short-process spinning process is adopted. The process flow is:

BC262 and Mao (sinceDynamic cotton feeding machine)→A186 carding→FA306 head bundling→FA306 two bundling→FA306 three bundling→FA306 four bundling→FA458 roving→FA506 spun yarn→automatic winding

2.4 Problems and technical parameters in the spinning process

2.4.1 Technical measures for carding process

Since both aramid and flame-retardant viscose fibers are chemical fibers, the fibers have good uniformity, few impurities, and serious static electricity. The carding process must ensure less damage, focus on opening, and minimize the increase in knots caused by back flowers. It should mainly solve the problems of difficulty in carding into slivers and blocked inclined tubes. In order to improve the fiber transfer effect, the cylinder-cover plate intervals are 0.35, 0.35, 0.30, 0.30, 0.35mm, the sliver weight is 17.5g/5m, and the upper and lower rollers The spacing is 0.20mm, which improves the smoothness of each channel and reduces clogging and broken bars. The cylinder speed is 330r/min, the licker-in speed is 780r/min, the cover speed is 81mm/min, and the maximum speed is 17r/min. After the above process is put on the machine, the neps of the spun card sliver are 4 grains/g. The cotton mesh has good clarity and the appearance of the slivers is smooth and delicate.

2.4.2 Technical measures for drawing process

Since aramid and flame-retardant fibers have slight static electricity, we must focus on solving the phenomenon of winding rollers and rubber rollers during production. The main measures are:

(1) WSN type coating for drawing rubber rollers is better than acid-treated rubber rollers.

(2) Control the vehicle speed on the low side and the bell mouth on the small side to improve the cohesion of the strips.

(3) The full tube length is changed from 2km to 1.6km to reduce the friction between the sliver and the surface of the upper coiler.

Drawing adopts four passes, the front roller linear speed is 190m/min, the bell mouth is 2.4mm, the cooked sliver weight is 19.5g/5m, and the roller spacing is 9×20mm.

2.4.3 Technical measures for roving process

Reasonable selection of the roving twist coefficient should not only improve the cohesion between fibers, but also prevent “hard ends” from the roving. The optimized twist coefficient was set to 71. When spinning, the spinning tension should be kept small to reduce accidental elongation of the yarn.

The roving basis weight is 5.5g/10m, the total draft is 7.09 times, the front roller speed is 180r/min, and the roller spacing is 10×26.5×3lmm.

2.4.4 Technical measures in the spinning process

The total draft of the spun yarn is 30.83 times, the back draft is 1.32 times, the twist coefficient is 376, the front roller speed is 183r/min, the roller gauge is 18×24mm, and the jaw gauge block is 3.0mm.

After testing, the spinning yarn indicators are: weight deviation +1.6%, evenness CV value 14.34%, fine details 5/km, thick places 55/km, neps 145/km, single yarn breaking strength is 17.58cN /tex, strong CV value 9.8%.

From the perspective of yarn quality, except for slightly more neps, other indicators are good. We believe that the main reason for the relatively large number of neps is the relative slippage between fibers and the kink caused by yarn drafting, which still needs to be overcome.

3. Other technical requirements

Because aramid fiber is very fluffy, has high elasticity, high elongation, and is easy to accumulate static electricity during processing; flame-retardant viscose fiber has low wet strength, poor abrasion resistance, poor cohesion between fibers, difficulty in strip formation, and fluffy yarn , there are difficulties such as high end breakage rate during spinning. The following measures should be taken during the spinning process:

(1) When spinning aramid, a high ambient humidity must be maintained to avoid static electricity accumulation. The relative humidity of carding is 65%, drawing is 62%, and spun yarn is 58%.

(2) Since the length of the aramid fiber is 44mm, the twist of the roving is not easy to be too high. Use a smaller basis weight and a smaller draft multiple, and increase the twist coefficient of the fine yarn appropriately, generally controlled at 370.

(3) The winding tension is controlled to be too small, and a chemical fiber splicer is used. The joint strength must ensure that it reaches 85% of the original yarn strength, and the appearance quality is good.

(4) The light fastness of aramid fiber after dyeing is only level 3, which requires further technical research.

4. Conclusion

By analyzing the characteristics of aramid fiber and flame-retardant viscose, and taking targeted technical measures during the production process, we successfully developed and produced a 30-count blended yarn of aramid fiber and flame-retardant viscose. The product quality has been improved. Customer approval.