Are flame retardant fabrics fabrics that cannot be burned?

Is Flame-retardant fabric cloth that cannot be burned?

When it comes to flame retardant, some people may think of high temperature resistant materials, so what is the difference between the two?

The difference between flame retardant and high temperature resistance

Simply put, high temperature resistant materials can still maintain their original properties under high temperature conditions, such as wear resistance, sealing, etc. That is to say, under high temperature conditions, its chemical properties basically do not change, and at the same time, try to ensure that the physical properties do not change.

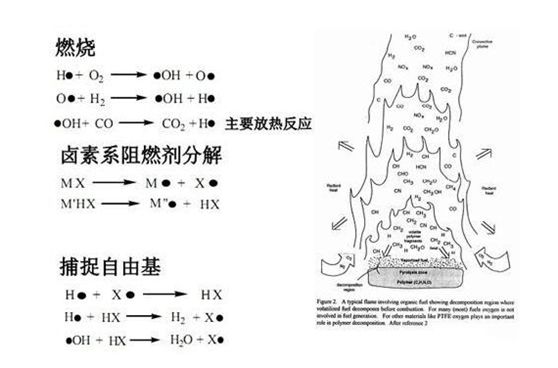

Flame retardant materials usually have the characteristics of not burning when exposed to flame, or not easy to burn, and extinguishing quickly after leaving the flame. For example, some polymer materials containing bromine and phosphorus can absorb the free radicals generated by combustion when burning. , hindering the chain reaction.

Are flame retardant fabrics fabrics that cannot be burned?

In fact, flame retardant fabrics do not mean that they cannot burn. After processing, the fabrics can prevent the spread of flames and automatically extinguish within a certain period of time.

Therefore, the flame retardant performance of fabrics is usually evaluated from the burning rate, burning time (afterburning time and smoldering time) and damage length of the fabric. That is, the shorter the flaming burning and flameless burning time, the greater the degree of damage. If it is low, the flame retardant performance of the fabric is better; on the contrary, it means that the flame retardant performance of the fabric is poor.

Related terms

Afterburning time: Under specified test conditions, the time the material continues to burn with flame after the fire source is removed.

Smoldering time: Under the specified test conditions, when the flaming combustion has terminated, or if it was a flameless burning, the ignition source is removed, and the time the material continues to burn without flames.

Damage length: under specified test conditions, the maximum length of the damaged part of the material in the specified direction.

Share high-quality courses directly with people who need them, and you can also get sharing commissions after others purchase the courses.

We all know that textile fabrics are flammable, and some work clothes for special types of work need to be flame retardant, such as fire-fighting suits, welding suits, etc.

Firefighting suit (left); welding suit (right)

So how does flame-retardant fabric achieve the “flame-retardant” effect?

1

Flame retardant fabric

Flame-retardant fabrics refer to fabrics that, even if ignited by an open flame, can automatically extinguish within 2 seconds of leaving the open flame. That is, they will ignite when exposed to fire and cease immediately after leaving the fire, blocking combustion and preventing secondary damage. Flame retardant fabrics can be divided into finishing flame retardant fabrics and fiber flame retardant fabrics.

Flame-retardant fabrics can be divided into four categories based on the number of times they are washed: permanent flame-retardant fabrics, wash-resistant (more than 50 times) flame-retardant fabrics, semi-wash-resistant flame-retardant fabrics, and disposable flame-retardant fabrics.

1

Finishing flame retardant fabric

It is produced through coating and auxiliary treatment during dyeing and finishing, and is generally used to produce things that are not washed frequently.

2

Fiber flame retardant fabric

It has permanent flame retardancy and good thermal stability. For example, acrylic fiber is a modified acrylic fiber. It is a copolymer of acrylonitrile monomer and a vinyl compound containing flame retardant elements. It has a wool-like feel and high flame retardancy, and is acid and chemical resistant. .

Because the cost of fiber flame retardancy is high, domestic flame retardant fabrics currently use more post-finishing methods.

2

Flame retardant principle

The basic principles of fabric flame retardancy include surface coverage flame retardancy, endothermic flame retardancy, condensed phase flame retardancy, gas phase flame retardancy and droplet effect.

1. Surface covered with flame retardant

Use some substances that melt when heated and can form a protective film on the fiber surface after cooling, or can produce non-flammable gas when heated to isolate the air on the fiber surface and hinder the supply of oxygen, thereby achieving the flame retardant effect.

2. Heat-absorbing and flame-retardant

Through the endothermic reaction of the Z-retardant during combustion, it absorbs more heat and reduces the temperature of the burning area to achieve the purpose of flame retardancy.

3. Condensed phase flame retardant

Flame retardants are used to affect the decomposition process of fibers and reduce the generation of flammable gases. This method is especially suitable for cellulose fibers.

4. Vapor phase flame retardant

During the combustion process, a large number of free radicals are generated, and adding inhibitors can prevent the propagation of flames by free radicals.

5. Droplet effect

Chemical fibers such as nylon and polyester will melt and shrink when heated, reducing their surface area or dripping away from the fire source, hindering combustion.

Flame retardant mechanism

3

Flame retardant applications

Due to its unique properties, flame-retardant fiber has broad application prospects in civil, military and industrial fields. It can not only be used in flame-retardant textiles for cars, trains, and aircraft, but also can be used in aerospace flame-retardant composite materials. , decorative textiles for hotels, restaurants and other public places, protective clothing for hospitals, military, forest firefighting and home textile products, etc.

The use of flame retardants makes cotton and wool fibers have flame retardant properties after flame retardant finishing, while synthetic fibers such as polyester and aramid have flame retardant properties through fiber modification. Aramid flame-retardant fiber products have a soft feel, good fluffiness, drape, moisture absorption and breathability, high strength, abrasion resistance, drape, good cloth surface finish, color fastness, and resistance to carbonization when exposed to fire. It has excellent properties such as melting and dripping, thereby meeting the quality requirements of high-end and high-end flame-retardant clothing and decorative fabrics.

4

Flame retardant performance test

GB 8965.1-2009 “Protective Clothing – Flame Retardant Protection Part 1: Flame Retardant Clothing” stipulates that the flame retardant performance of flame retardant fabrics is actually only one of the requirements for protective clothing. Flame-retardant clothing is suitable for use in places where there are open flames, emitting sparks, operating near molten metal, and in places where there are flammable substances and there is a risk of fire. It is not suitable for flame-retardant protective clothing worn in fire rescue.

1

Our country currently mainly uses GB/T 5455-2014 “Vertical Method for Textile Combustion Performance Testing” to test the flame retardant properties of textiles. The principle is to use the flame generated by the specified igniter to ignite the center of the bottom edge of the vertical sample. After the specified ignition time, measure the afterburning time, smoldering time and damage length of the sample. This method can be used to determine the flame retardant properties of various fabrics and products such as clothing, decoration, and transportation interiors.

Vertical combustion test chamber

2

GB 31701-2015 “Technical Specification for Safety of Textile Products for Infants and Children” requires the use of GB/T 14644-2014 “Determination of Combustion Properties of Textiles at 45° Direction of Burning Rate” to test the combustion performance of infants and children’s clothing. The principle is as follows , under specified conditions, ignite the surface of the sample placed at an angle of 45°, and evaluate the burning rate of the sample based on the flame spread time. The ignition of the velvet sample and the base fabric is used as an additional indicator of the intensity of burning. This standard also applies to all types of fabrics and their products.

45° combustion test chamber

In summary, the market demand for flame-retardant fibers is increasing day by day. Chemical fiber companies must not only increase their efforts to develop new flame-retardant fibers, but also improve technology and equipment to improve the comprehensive quality of existing flame-retardant fibers to meet the needs of civilian, military and industrial applications. Use requirements for high-end flame retardant textiles.