Advanced Composite Materials Lecture Notes Collection Collection Edition

AdvancedComposite Materials Lecture Notes Collector’s Edition

Laminated structure

Composites are made from a combination of materials mixed together to achieve specific structural properties. The individual materials do not completely dissolve or fuse into the composite, but they work together as a whole. Typically, the interfaces between components can be physically identified. The properties of composite materials are better than those of the individual materials they are composed of.

An advanced composite material is made from fibrous materials dissolved into a resin matrix, often laminated with alternatingly oriented fibers to provide the material’s strength and stiffness. Fibrous materials are not common; wood is the most common fibrous structural material known to man.

Applications of composite materials in aircraft include

•Deflector

•Flight control surfaces

•Landing gear doors

•Leading and trailing edge panels of wings and stabilizers

•Internal components

• Floor beams and floor panels

•Vertical and horizontal stabilizer main structures for large aircraft

•Main wing and fuselage structures of new generation large aircraft

•Turbine engine fan blades

•Propeller

Main components of laminates

Isotropic materials have uniform properties in all directions (referring to isotropic properties of the same material). The measured properties of isotropic materials are independent of the test axis. Take the metallic materials aluminum and titanium as examples to illustrate examples of isotropic materials.

Fibers are the main load-bearing elements of composite materials. Composite materials have strength and stiffness only in the direction of the fibers. Unidirectional composites have mechanical properties primarily in one direction, known as anisotropy, where their mechanical or physical properties differ from the direction of the natural reference axis inherent to the material. Parts made from fiber-reinforced composites can be designed with fiber orientations that produce optimal mechanical properties, but they can only approach the truly isotropic properties of metals, such as aluminum and titanium.

The composite matrix supports the fibers and binds them within the composite material. The matrix transfers any applied load to the fibers, keeps the fibers in their position and chosen orientation, gives the composite’s environmental resistance, and determines the composite’s maximum service temperature.

Strength properties

The structural properties of composite laminates, such as stiffness, dimensional stability and strength, depend on the stacking sequence of the laminates. The stacking sequence describes the distribution of ply directions through the thickness of the laminate. As the number of layers with selected orientations increases, more stacking sequences are possible. For example, a symmetrical eight-layer laminate with four different lay-up directions has 24 different stacking sequences.

fiber direction

The strength and stiffness of a composite depends on the oriented sequence of the plies. The actual strength and stiffness of carbon fiber range from low, as provided by glass fiber, to high, as provided by titanium fiber. The range of this value is determined by the direction of the load exerted by the laminate. In advanced composites, proper selection of lay-up directions is necessary to provide efficient designs of structures. This section may require a 0° layer to respond to axial loads, a ±45° layer to respond to shear loads, and a 90° layer to respond to lateral loads. Because strength design requirements are a function of the direction of applied load, the layup direction and layup sequence must be correct. During the repair process, it is crucial to replace each damaged layer with a layer of the same material and orientation.

The fibers in a monolithic material move in one direction, and the strength and stiffness are only in the direction of the fibers. Prepreg (prepreg) tape is an example of unidirectional layup orientation.

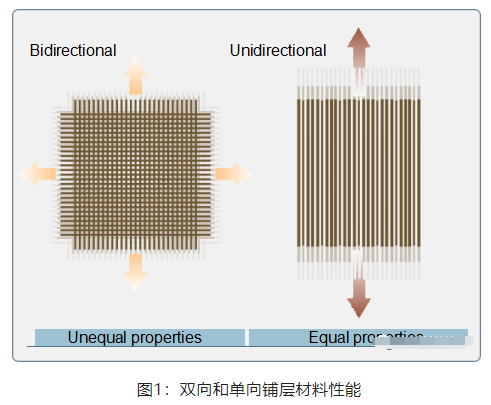

Fibers in bidirectional materials flow in both directions, usually 90° apart. Plain weave construction is an example of a bidirectional layup orientation. These ply directions have strength in both directions, but not necessarily the same strength. As shown in Figure 1

The sequence of quasi-isotropic bedding is 0°, -45°, 45° and 90° or 0°, -60° and 60°. As shown in Figure 2, these types of ply orientations simulate the properties of isotropic materials. Many aerospace composite structures are made from quasi-isotropic materials.

Bidirectional and unidirectional layup material properties

Symmetrical isotropic material layup

portrait

The warp direction refers to the longitudinal fibers of the fabric. The warp direction is the direction of high strength due to the straightness of the fibers. Warp warp is used to describe the direction of fibers on a diagram, specification sheet, or manufacturer’s sheet. If there is no warp direction on the fabric, the warp direction defaults to zero when the fabric comes off the roll. So 90° to zero is the width of the fabric. As shown in Figure 3

twist lock

fiber morphology

All product forms typically start from unidirectional strands of raw fiber, packaged into continuous strands. An individual fiber is called a filament. The word “thread” is also used to refer to an individual fiberglass. Bunches of filaments can be classified as spun yarns, yarns or rovings. Fiberglass yarn is twisted, Kevlar® yarn is not. There is no twisting force in the tows and rovings. Most fibers are dry and need to be impregnated with resin (pre-preg) before use

Dry fabric materials (from top to bottom: aluminum lightning protection material, kevlar®, fiberglass and carbon fiber)

Auxiliary (thixotropic agent)

The additive (thixotropic agent) is gel-like when stationary and becomes liquid when stirred. These materials have high static shear strength and low dynamic shear strength while losing viscosity under stress.

Adhesive

Film adhesive

Structural adhesives used in aerospace are typically supplied in film form, supported on release paper, and stored under refrigerated conditions (-18°C, or 0°F). Film adhesives are available using high temperature aromatic amines or catalytic curing agents with a wide range of flexibilizers and tougheners. Rubber toughened epoxy film adhesives are widely used in the aviation industry. The upper temperature limit of 121-177°C (250-350°F) usually depends on the degree of toughening required and the overall selection of resin and curing agent. Generally speaking, toughened resins result in lower service temperatures. Film materials are often fiber-supported to improve handling of the film prior to curing, control adhesive flow during bonding, and assist in controlling bond line thickness. The fibers can be made into short fiber mats with random orientation or into woven cloth. Common fibers include polyester fiber, polyamide fiber (nylon) and glass fiber. Adhesives containing woven fabrics may experience slight degradation in environmental performance as water is absorbed by the fibers. Random mats are not as effective as wovens in controlling film thickness due to the movement of unrestrained fibers during the bonding process. Spun-twisted non-woven fabrics do not move and are therefore widely used. As shown in Figures 13 and 14

Uses film adhesives, Kevlar®, fiberglass and carbon fiber

A roll of film

Adhesive

Paste adhesives as an alternative to film adhesives. These are often used for secondary bonding to repair damaged parts of the patch and are used where film adhesives are difficult to apply. In epoxy resin, the slurry is mainly used to stick to the structural adhesive. One-part and two-part systems are available. The advantage of pasting adhesive is that it can be stored at room temperature and has a long shelf life. The disadvantage is that the thickness of the bonding line is difficult to control, which affects the strength of the bond.

When applying adhesive, the fabric can remain glued during the bonding process. As shown in Figure 15

A B mixed adhesive

Foam adhesive

Most foam adhesives are 0.025″ to 0.10″ thick Class B epoxy. Foam adhesive cures at 250°F (121°C) or 350°F (176°C). During the cure cycle, the foamed adhesive expands. Foaming adhesives need to be stored in the refrigerator, and like prepregs, they have a limited storage life. In pre-repair, foaming adhesive is used to splice over the honeycomb in a sandwich structure and repair in the existing core. As shown in Figure 16

Use foam adhesive

Sandwich structure description (sandwich structure description)

In theory, sandwich construction is a structural panel concept consisting of two relatively thin, parallel facing layers separated by a relatively thick or light core material. The core support surface resists bending and resists out-of-plane shear loads. The core material must have high shear strength and compressive stiffness. Composite sandwich structures are typically manufactured using high-pressure tank curing, press curing, or vacuum bag curing. Skin stacks can be pre-cured and then bonded together in a co-curing operation, or a combination of both methods. Examples of honeycomb structures are: wing breakers, slides, ailerons, flaps, nacelles, floors, and rudders. As shown in Figure 17

honeycomb sandwich structure

Performance

In a comparison of aluminum and composite panel structures, the bending stiffness of sandwich structures is very high. Most honeycombs are anisotropic, meaning their properties are directional. As shown in Figure 18, the advantages of using a honeycomb structure are illustrated. Increasing core thickness greatly increases the stiffness of the honeycomb structure with minimal weight increase. Due to the high stiffness of the honeycomb structure, there is no need to use external hard panels, like beam frames. As shown in Figure 18

Strength and stiffness of honeycomb sandwich materials compared to solid laminates

surface material

Most honeycomb structures used in aircraft construction have aluminum, fiberglass, kevlar® or carbon fiber facings. Carbon fiber face sheets cannot be used with aluminum honeycomb core material as it causes corrosion of the aluminum. In high-temperature structures, titanium and steel are used for specialty applications. The surface materials of many components, such as spoilers and flight controls, are very thin, sometimes only 3 to 4 mm thick. Parameter reports show that these panels do not have good impact resistance.