Transfer printing from order receipt to production process: essential information for merchandisers and salespeople

Transfer Stamping From order receipt to production process: essential information for merchandisers and salespeople

Today, I write this article that I wrote ten years ago. I hope it will be helpful to you when receiving transfer stamp orders.

The basic process of transfer printing:

Get a pattern provided by the customer and ask for a complete pattern or file (AI, PDF is better). Get it to the transfer printing factory as soon as possible and let them help you complete the drawing, digital sample, and plate making. , go to the computer for color grading and proofing. All you have to do is confirm and modify your opinions.

1Scan and trace the original or document

2 computer color separation channels

3. Consider the printing shrinkage, consider the expansion and contraction of the pattern when printing on a large machine, confirm the size of the pattern, whether the color matching channel and the pattern are correct, how many patterns can meet the color matching requirements, the digital printer produces a digital sample, and press it on the pre-printed pattern. Printed fabric provided to final customer for confirmation.

4. Plate making: Engraving the gravure printing roller.

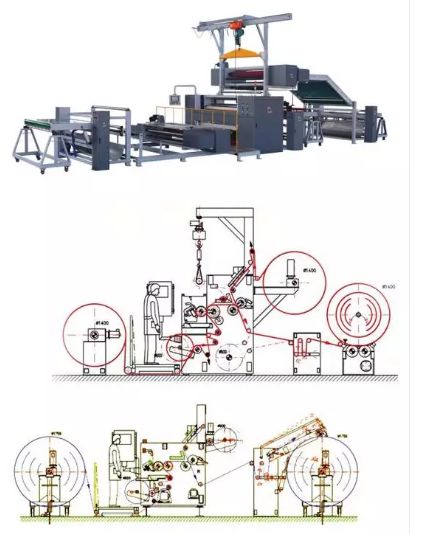

5. Print water-based or oil-based disperse dyes on paper or other carriers through a gravure printing machine.

6. The sublimation transfer printing machine is conveyed through a high-temperature resistant blanket, and the heat is pressed at 200 degrees for 15 seconds to pad-print onto the product to be printed, which is mainly knitted polyester fabric.

1. Transfer printing characteristics

(1) Transfer printing patterns have the characteristics of realistic patterns, detailed patterns, clear layers, and strong three-dimensional effect. Transfer printing can print flowers, cartoons, portraits, natural scenery and artistic patterns.

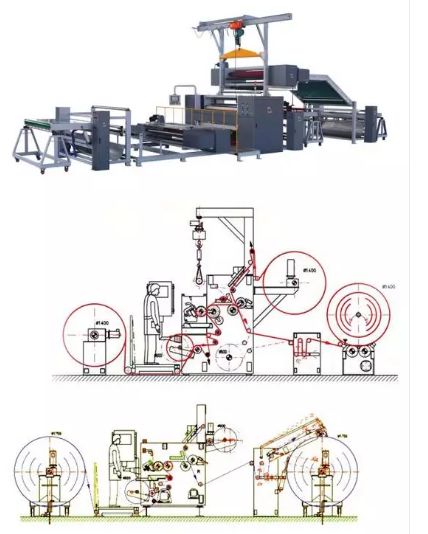

(2) Transfer printing equipment has the characteristics of simple structure, small footprint, low investment, and high economic efficiency. Since the equipment is tension-free processing, it is suitable for printing on knitted and woven fabrics of various thicknesses. In addition, after transfer printing, it can be packaged and shipped without post-processing.

(3) The transfer printing process is environmentally friendly, can withstand various tests, and has no environmental pollution problems. Due to dry processing, there is no need for washing, steaming, drying and other processes, so there is no waste gas and waste water discharge.

(4) Transfer printing has the advantages of high production efficiency, labor saving and easy operation.

(5) Transfer printing uses the three primary colors of red, yellow and blue plus black. Only 4 sets of colors can be used to achieve photo and painting effects.

2. Transfer printing mechanism

Transfer printing is mostly used on polyester fabrics. It is a printing method that uses high temperature (around 200°C) to heat the disperse dyes in the printing paper into a gas phase, condense on the surface of the polyester, then penetrate into the amorphous area of the fiber macromolecules, and fix it inside the fiber after cooling.

3. Requirements for transfer printing on fabrics

Transfer printing is mainly used on polyester fiber products, that is, 100% polyester fabrics. Don’t try fabrics with animals and plants as their main raw materials, such as cotton, linen, silk, wool, artificial cotton, etc.

1 For fabrics used in transfer printing, general transfer printing factories do not have pre-pressing equipment. Pre-processing such as machine washing, bleaching and dyeing, shaping, and softening must be done in the dyeing factory. The transfer printing process is not affected by softeners.

2. Only light colors such as bleach and natural white can be printed on dark colors, but dark colors cannot be printed on light colors.

3. The sublimation temperature is 200°C, and the hot pressing lamination time is 15 seconds. Different fabrics will have different shrinkage rates. Generally, a shrinkage rate of 2-3% is considered. For those with higher requirements for door width or pattern positioning, during plate making Pay special attention to the confirmation and finalization of the dyeing factory. For some stretchy fabrics, you have to consider the tension when putting them on the machine and rolling them, as they will become narrower and longer. The key point is to rather be big than small, and wide rather than narrow.

4. Several points to note when transferring printing:

1. Some four-color color drafts and design drawings imitate digital patterns. Since the color can be changed in any area at will, we do not consider that in the future we will divide spot color channels into plate making for mass printing. The biggest difference between spot color separations is One color is on the same plate. For example, if the color of a flower is red, this red shade transition layer is superimposed in other places, and the color combination on other pages is converted into another reddish color. If you want to change the flower to be blue, other places will follow. The color of the plate will also change from blue to another bluish color.

Remember: the color matching of the printing factory’s digital plate-making sample shall prevail.

2. When confirming the digital sample, you should compare it carefully. The shrinkage of the fabric mentioned earlier, the tension of the cloth during printing and the rolling of the fabric are all closely related to the size of your current digital sample. Once you confirm the engraving and plate making, and then find out, what is waiting for you is to re-make the plate, not to mention paying a large amount of plate making fees.The delivery date will be delayed.

3 Confirm the feel of the finished printed fabric. Applying softener will not have much impact on transfer printing.

4 Due to high temperatures, various coatings will be damaged. It is recommended to print first, and then do coating, lamination and other post-finishing processes.

5 There are roughly two types of printing paper on the market. One is recycled paper. The advantage is that the price is lower. The disadvantage is that due to the color spots and pulp spots on the original paper, it is easy to have small color spots and white spots on the fabric. Especially when doing gradients, it is particularly obvious. The second type is made entirely of wood pulp. The advantage is that there are no color spots or white spots. The disadvantage is that the price is higher. When our customers’ requirements are relatively high, you have to insist that the customers not be short of a few cents and take the risk.

6. The inks used in transfer printing are also divided into ordinary and high-end. The biggest difference is the light fastness, and the price sometimes differs by a few cents per meter. It is better to ask the customer clearly about the light fastness requirements. The ordinary inks from our factory can pass the test of water washing, dry grinding, machine washing, soaping, environmental protection, color adhesion and so on, and can reach level 4 or above on polyester fabrics. But when it comes to sunlight fastness, especially for blue, when you have high requirements for customers, especially for clothing fabrics, you should not take any chances and must use high-grade ink with high fastness.

7. All digital samples are only used to confirm the size of the pattern. The pre-production samples for large quantities must be based on the large quantity when the printing factory goes on the machine to color. Nowadays, some customers have very high requirements for the color matching of digital samples and require confirmation during the digital sample process. This process is very time-consuming and laborious. But in fact, the colors and effects when using the main computer are what you should be optimistic about and keep an eye on.

8. It is important to choose a transfer printing factory. Choose a good printing factory, he can be responsible for your products and his own reputation. Sometimes in order to save a little printing cost, it is not cost-effective to lose fabrics and even customers.