Aramid fiber: domestic alternative opportunities for lithium battery coating films

Aramid fiber: domestic alternative opportunities for lithium battery coating films

Core ideas:

Aramid has excellent performance and can replace PVDF as lithium battery coating film. As domestic aramid companies self-produce coating films, economies of scale can reduce costs and improve efficiency, reaching commercialization conditions. Downstream demand such as automobiles, aviation, security, etc. continues to grow rapidly. , integrated aramid coating companies have unexpected opportunities, such as Taihe New Materials, Sinochem International, etc.

Catalyst:

Domestic aramid companies make their own coating films, and the scale effect and cost advantages of aramid integration are etc.

risk warning:

The downstream demand for aramid fiber is lower than expected, the coating penetration rate is lower than expected, and the cost reduction due to scale effect is lower than expected, etc.

1. Aramid: aromatic polyamide man-made fiber with a wide range of applications

The full name of aramid fiber is “aromatic polyamide fiber”. According to its molecular structure, it is roughly divided into “fully aromatic polyamide fiber” and “heterocyclic aromatic polyamide fiber”. The former is subdivided into polyisophthalylated isophenylene. Diamine (also known as para-aramid, aramid 1414), polyparaphenylene terephthalamide (also known as meta-aramid, aramid 1313), poly-para-benzamide fiber, poly-m-phenylene amide fiber, Copolymer aramid fiber, etc., among which meso-aramid and para-aramid have achieved industrial production. Aramid, carbon fiber and ultra-high molecular weight polyethylene fiber are all three high-performance fibers. They have excellent properties of flame retardant, high temperature resistance, electrical insulation, high strength, high modulus and corrosion resistance. They were born in the 1960s. It is a product of the arms race between the United States and the Soviet Union during the Cold War. At the beginning, it was mostly used in military fields such as aerospace and strategic materials. After the end of the Cold War, it was gradually used in civilian fields such as personal protection, environmental protection, information and communications, electronics and electrical.

Due to structural differences, the performance and uses of the two are different and they correspond to different downstream applications. Among them, para-aramid has the characteristics of high strength and high modulus, and is mainly used in fields that require high-temperature-resistant bulletproof armor, optical cables, and high-strength ropes for rubber products. Meta-aramid has excellent high temperature resistance, flame retardancy and insulation, and is mainly used in high temperature protective clothing, filter materials, electrical equipment and other fields.

2. As a lithium battery coating material, aramid has low cost, excellent performance and strong scale effect.

First of all, the power lithium battery separator is an important component that determines the safety of lithium batteries, because the separator is the key material to prevent battery fire. Many battery fire accidents occur precisely because the separator is damaged. The separator is one of the four main materials of lithium batteries and is known as the “third pole” of lithium batteries.

In layman’s terms, a separator is just a layer of plastic film. The diaphragm looks ordinary to the naked eye, but in fact its surface is densely covered with nanometer-scale micropores. This micropore is the key to the function of the separator, and micropore preparation is also the core technology of separator production.

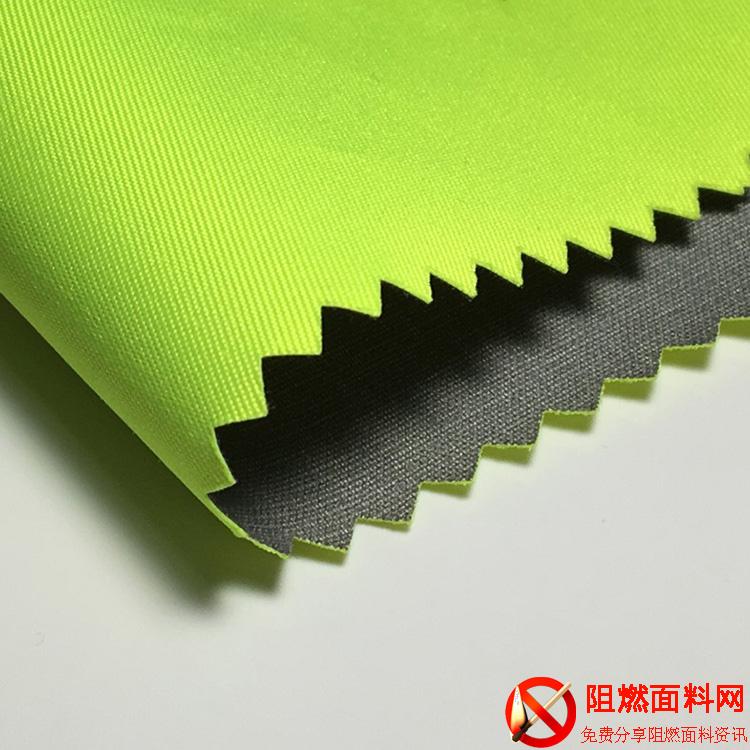

Currently, common lithium-ion battery separators are usually polypropylene, polyethylene or a composite film of both. The melting point of these materials is usually lower than 170°C. However, when the battery heats up due to internal or external reasons, the separator will melt and shrink. The positive and negative electrodes will come into direct contact, resulting in a short circuit, causing battery combustion, explosion and other accidents, posing safety risks to use. . Current coatings include water-based (boehmite, alumina + inorganic solvent) and oil-based coating materials represented by PVDF, PMMA and aramid. Among them, water-based coating is mainly used for lithium iron phosphate batteries, accounting for more than 70%. Water-based coatings and oil-based coatings are usually mixed in different proportions to complement each other through double-sided multi-layer coating, single or mixed methods to meet membrane requirements.

At present, aramid coating has been fully used on the NCA batteries supplied by Panasonic to Tesla. Aramid coating has the characteristics of both organic and inorganic materials, has the best performance and is thin and light. The coating is about 1.5μm, while PVDF mixed coating is usually Above 2μm (PVDF+ ceramic). In addition, the density of aramid is one of the lowest among all coating materials, being 40% of ceramics, 50% of PMMA, and 80% of PVDF.

From a cost perspective, aramid coating materials are much more cost-effective than PVDF. PVDF is driven by the demand for downstream lithium batteries and photovoltaics, with prices starting from 90,000 yuan/�It has risen to 400,000 yuan/ton, of which the separator coating with PVDF is about 200,000 yuan/ton, while the cost of film production by aramid factories such as Taihe New Materials has dropped from 5-6 yuan/square meter to 2-3 yuan/square meter. The base film + coating integrated enterprise will obtain the best cost in the industry.

3. Market space and main leaders of aramid coating

Referring to the predictions of Gaogong Lithium Battery EVtank, the total global lithium battery shipments in 2025 will be 2102GWh, including 1550GWh of power batteries, 390GWh of energy storage lithium batteries, and 162GWh of consumer batteries. According to the announcement of Sinoma Technology, a single GWh power battery will require 15 million square meters of separator in 2025. The global demand for separators reaches 31.5 billion square meters in 2025. If the penetration rate of coated separators is 70%, the corresponding market space is 22.1 billion square meters. Assuming that the growth rate of single-sided coating and double-sided coating is 40% in 2025, the average price is 4 yuan/square meter, conservatively calculated based on 5% permeability of aramid coating in the coated separator, corresponding to 4,767 tons of aramid demand in 2025, corresponding to a market space of 4.4 billion yuan; calculated based on 10%, corresponding to the aramid demand in 2025 It is 9,534 tons, corresponding to a market space of 8.8 billion yuan.

From the perspective of competition, separator coating is dominated by Japan’s Teijin and Sumitomo. Domestic manufacturers Taihe New Materials and Sinochem International are actively deploying, and Enjie Co., Ltd. has obtained Teijin’s patent authorization. The meta-aramid fiber industry is highly concentrated, and Taihe New Materials ranks among the top players.

Meta-leading companies mainly include DuPont of the United States, Teijin Zhongtai and New Materials of Japan. Among them, DuPont of the United States and Teijin of Japan were the first to realize the industrial production of meta-aramid. According to data from Huajing Intelligence Network, as of 2021, the global production capacity of meta-aramid fiber will be 53,000 tons, of which overseas leader DuPont has a production capacity of 30,000 tons, occupying an absolute dominance. The domestic production capacity of Taihe New Materials is 11,000 tons of meta-aramid, and its global production capacity market share exceeds 20%, second only to DuPont. Taihe New Materials plans to achieve a total production capacity of 20,000 tons in 2025. Taihe is expected to start the transition from a domestic leader in meta-aramid fiber to a global leader, further increase its market share and accelerate the further expansion of downstream applications.

Main competitive landscape of meta-aramid fiber

Why is it said that there are unexpected opportunities in the integrated aramid coating industry chain? Different companies have different costs for raw tea aramid coating films. For example, if a base film factory produces aramid coating film and needs to purchase raw materials from overseas aramid suppliers, the price will be around 700,000 yuan/ton. The scale advantage is not outstanding, and the unit cost will reach more than 5.6 yuan/square meter. The coating factory’s self-made aramid film has a raw material cost of 100,000 yuan/ton, and external sales of 500,000-600,000 yuan/ton, with a cost of about 2.5 yuan/square meter; the integrated base film (aramid) coating is cheaper, According to calculations, the cost of the diaphragm can reach 1.5 yuan/square meter, achieving the best cost in the industry.

Cost of aramid coating film from different companies

Sinochem International and others have deployed 5,000 tons/year of para-aramid. Taihe New Materials is also planning to achieve 21,500 tons of para-aramid in 2025 based on its existing production capacity of 6,000 tons of para-aramid and 17,000 tons of meta-aramid. 20,000 tons of aramid and meta-aramid. Achieve economies of scale, further reduce the cost of aramid coating films, and respond to downstream needs.

Enjie Co., Ltd. has obtained the patent authorization of Teijin’s PVDF and aramid coating, and supplies 30% of Panasonic’s separators. It is expected to enter Panasonic’s aramid supply chain in 2023, and Panasonic + Tesla are expected to account for an estimated share of the company’s shipments in 2025. The ratio reaches 10%.