Today, various types of PTFE products have played a decisive role in the national economy such as chemical industry, machinery, electronics, electrical appliances, military industry, aerospace, environmental protection and bridges. . Polytetrafluoroethylene (PTFE) usage conditions industry chemical, petrochemical, oil refining, chlor-alkali, acid production, phosphate fertilizer, pharmaceuticals, pesticides, chemical fiber, dyeing, coking, gas, organic synthesis, non-ferrous smelting, steel, atomic energy and polymer filter materials , High-purity product production (such as ion membrane electrolysis), viscous material transportation and operation, food, beverage and other processing and production departments with highly strict hygiene requirements.

Polytetrafluoroethylene film is made of polytetrafluoroethylene as raw material Microporous membranes formed by puffing and stretching are widely used as a basic performance material. The stretching process of PTFE is a process in which fine fibers are continuously pulled out from the folded lamellae and become longer and thinner. During the unidirectional stretching (longitudinal stretching) process of the PTFE calendered film, the thin fibers are continuously pulled out, forming nodes composed of island nodes composed of unstretched crystal regions and slender fibers connecting the nodes. ——Fiber structure.

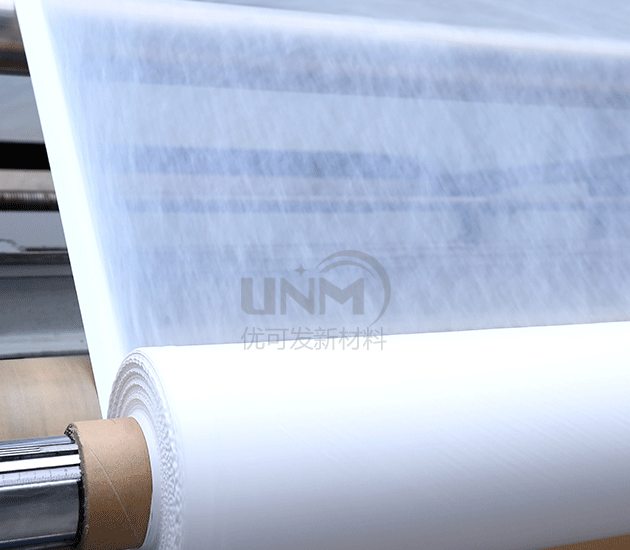

Polytetrafluoroethylene film adopts a biaxial stretching process and can be used for atmospheric dust removal, air purification, etc. The pore size of the film can be controlled to 0.2 um, the porosity can reach more than 88%. It is compounded with various filter materials such as needle felt, machine-made cloth, non-woven fabric, glass fiber, etc. to obtain a coated filter material with surface filtration performance, so that the PTFE coated filter material has peeling strength. It has the characteristics of high air permeability and uniform pore size distribution. As a dust bag or pleated dust filter cartridge, it is installed in the dust removal equipment to quickly intercept fine dust measured in microns, and the dust removal efficiency can reach more than 99.99%.

Is a high-tech enterprise focusing on the R&D, production and sales of polytetrafluoroethylene film. The products we produce are Produced using imported raw materials, the molecular weight is finer, cleaner and has good uniformity. Moreover, we have a full set of advanced PTFE film production equipment and testing instruments, as well as a complete pre-sales, sales and after-sales service system. If you are interested, please enter the store for consultation.

</p