The main uses of Oxford cloth:

Oxford cloth can be subjected to post-finishing processes according to the needs of different uses, such as dyeing, waterproofing, anti-static, mildew-proof, moisture-proof, fire-proof, UV-proof, anti-bacterial, PVC/PU/PA coating, Compounding, printing, etc. Therefore, Oxford cloth is used in various industries.

1. Outdoor series: outdoor tents, carports, awnings, rain gear, mobile outdoor tents, wild camping, Pergola, floor mats, etc.

2. Luggage series: trolley suitcases, satchels, notebook bags, business bags, satchels, tool bags, cosmetic bags, handbags, etc.

3. Stroller series: strollers, baby carriers, baby waist stools, Child seats, baby toy storage bags, safety fences, etc.

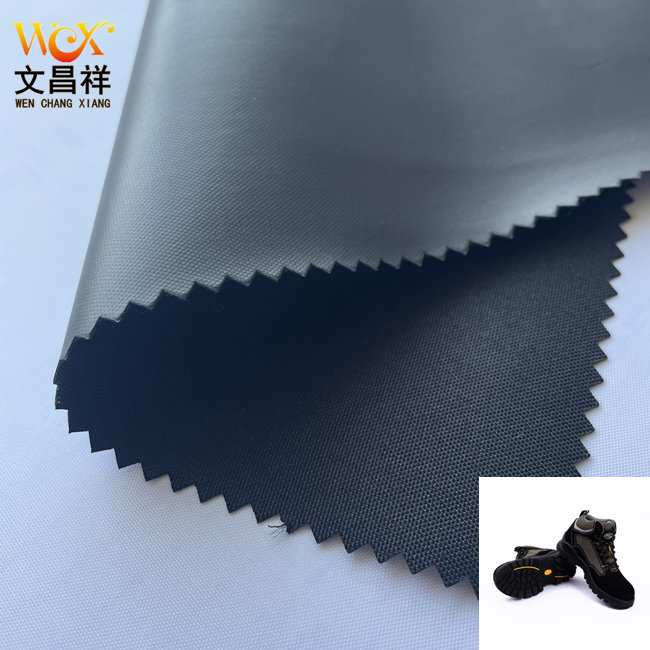

4. Home series: wardrobe cabinets, storage boxes, suits bags, aprons, etc.) as well as shoe material fabrics, rehabilitation equipment fabrics, etc.

5. Car series: storage boxes, buckets, sunshade curtains, child seats, car outdoor tents, car clothing, etc.

Making flood and rainproof supplies: Oxford cloth The warp of the fabric uses 200D nylon air-conditioned yarn, and the weft uses 160D nylon air-conditioned yarn as raw material. It has a plain weave structure and the product is woven by water jet. After being dyed, finished and coated, the gray fabric has the advantages of soft touch, strong drape, novel style and excellent waterproof performance, and the cloth has the luster effect of nylon silk.

Making bags: Using thick-point changing permeable structures interwoven on a fountain loom. After the fabric is relaxed, refined, pre-shaped, alkali reduced, and softened and set, the reverse side of the fabric is then passed through a rubber-plastic polyester layer. Bags made of this fabric are favored by the majority of people who pursue beauty because of their fashionable appearance, delicate and soft texture, and excellent waterproofness.

Making clothes, pants and shoes: Oxford cloth weaving process uses weft strips in water-jet weaving (with dobby faucet ) are intertwined. The fabric strips are clearly visible, integrating modernity, artistry and drape. After being dyed, embossed or calendered, gray fabric has the advantages of strong drape and good waterproofness. This material is now also used in the production of casual and fashionable shoes. Due to the characteristics of the fabric itself, there are plenty of choices for outfits.

Specification classification of Oxford cloth and environmentally friendly recycled series: 1680D Oxford cloth, 1200D Oxford cloth, 900D Oxford cloth, 600D Oxford cloth, 420D Oxford cloth, 300D Oxford cloth, 210D Oxford cloth, 150D Oxford cloth, etc.; Classified by function: Flame-retardant Oxford cloth , waterproof and flame-retardant cloth, silver-coated flame-retardant cloth, pu waterproof oxford cloth, PVC oxford cloth, TPE, TPU, anti-UV, camouflage oxford cloth, fluorescent oxford cloth, composite oxford cloth, etc. Please consult customer service for details.

</p